|

Full Set Manual Pad Printer with Sealed Ink Cup Kit |

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the printing plate (clich¨¦) via a silicone pad onto a substrate (surface to be printed). Pad printing is used for printing on otherwise impossible products in many industries including medical, automotive, promotional, apparel, electronics, appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductive inks, adhesives, dyes and lubricants. Physical changes within the ink film both on the clich¨¦ and on the pad allow it leave the etched image area in favor of adhering to the pad, and to subsequently release from the pad in favor of adhering to the substrate (material being printed). The unique properties of the silicone pad enable it to pick the image up from a flat plane and transfer it to a variety of surface (i.e. flat, cylindrical, spherical, compound angles, textures, concave surfaces, convex surfaces). |

|

| Why use pad printing ? Pad printing is used for printing on various substrates like Plastics, Metals, Glass and Ceramics, Paper and Cardboard, Leather. However, it is primary used in places where the printing area is small and / or the contour or surface of the object is not flat or hard to reach by other printing process. |

|

* Engineering items * Golf products * Hangers * Highlighters * Key rings * Letter openers * Lighters* Mugs * Page up * Paper weights * Pens * Pencils * Rulers * Sunglasses |

* Ashtrays * Bicycle helmets * Brochure holders * Business card holders * Calculators * Cassettes * Coasters * Computer products * Construction helmets * Badges * Telephone boards * Toys * Mobile phone holders |

|

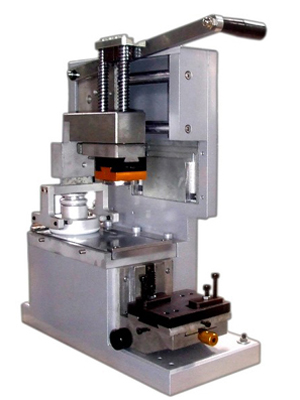

Manual Single Color Pad Printer with Sealed Ink Cup |

|

|

|

Main features

Parameters

ˇˇ |

|

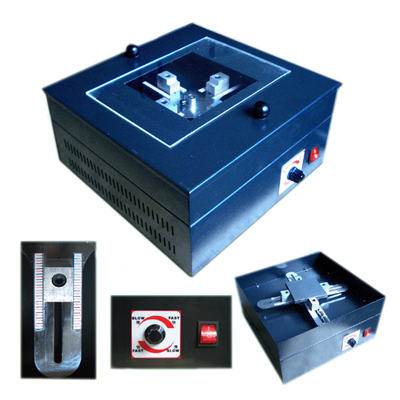

Emulsion Coating Machine |

|

|

Steel plate coating machine can coat photosensitive liquid evenly on surface of steel plate or steel blade by the centrifugal effect caused by high-speed rotation. It is one of the important equipments in the process of plate making and a necessary tool for making high quality plate.

ˇˇ |

|

12"X7.7"UV Exposure Unit |

|

Main features

. |

|

|

Parameters

|

|

Plate Making Liquid |

|

| These clich¨¦ making liquid allows the pad printer to take his film positive artwork and make inexpensive short run clich¨¦s. 1-Cleaning liquid 500ml /bottle 2-Photosensitive liquid 250ml /bottle 3-Developing liquid 250ml /bottle 4-Etching liquid 250ml /bottle 5-Stripping liquid 500ml/bottle 6-Syringe ˇˇ |

|

|

Steel Plate Clich¨¦ |

|

|

|

ˇˇ These pad printing steel plates use high quality steel, this steel is made to exacting specification for dimensional accuracy, parallelism, flatness and super hardened to ensure accurate, extra long lasting plate life. Produced for the pad printing industry.

ˇˇ |

|

Inkjet/Laser Transparency Film |

|

|

ˇˇ ASC Non-Waterproof Ink-Jet transparent Film is a specially coated, clear film that absorbs quick drying inkjet ink, and controls the shape of fine lines and half tones. This transparent inkjet film is only coated on one side. Print on the coated (matte) side of the film! If you print on the glossy uncoated side, the ink will not dry because it is not absorbed by the coating. Note 1: This film also can be used in your laser printer. A4 8"x12" (210x297 mm) ˇˇ |

|

Ink Thinner |

|

|

This ink thinner is formulated for both pad printing and screen printing and are available in various evaporative rates that support fine tuning of the ink to any printing situation. They have been specially formulated to minimize evaporative fluctuations, provide process

balance and enhance production output. This thinner can be used to dilute all kinds of plastic ink, PVC ink and others. 500ml/bottle ˇˇ |

|

|

Black PVC Ink |

|

|

PVC ink is the most popular ink used in pad printing, giving beautiful colors and designs to your favorite t-shirts and other items. It is also used for industrial printing clothing, on items such as dotted and anti-slip gloves. PVC ink requires fine particle resistant fast gelling at low temperatures, excellent opacity, qualities with good printability and anti-blocking. Finished printing features with excellent flexibility and weather resistance. 2.2LB(1kg)/can |

|

|

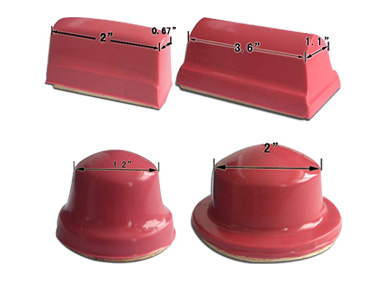

Pad |

|

|

Rubber head is a carrier which transfers the patterns on the steel plate onto the substrate surface. These pad printing rubber heads is with high print times and abrasion resistance, without any in purities, with good printing effects, permanent and durable. |

|

|

|

|

|

|

Items included

|

|

|

ˇˇ |