MR-13A Drill Bit Grinder

2. Don¡¯t attempt to use inappropriate attachments in an attempt to exceed the tools capacity. Approved accessories are available from the dealer or machine maker.

3. Check for damaged parts, before using any tool, any part that appears damaged should be carefully checked to determine that it will operate properly and perform its intended function.

4. Check for alignment and binding of all moving parts, broken parts or mounting fixture and any other condition that may affect proper operation. Any part that is damaged should be entirely or replaced by a qualified technician.

5. Do not use the tool if any switch does not turn off and on properly.

Change

The Wheel

Loosen

the knob screw, open the wheel cover, and then loosen the wheel center

screw and the fan in the spindle and take them out. After that, you can

take out the old wheel.

Clean the spindle and surfaces inside the wheel case before putting the

new wheel in, then put back the new wheel, center screw, the fan and

then tighten them. Close the cover, tighten the knob screw.

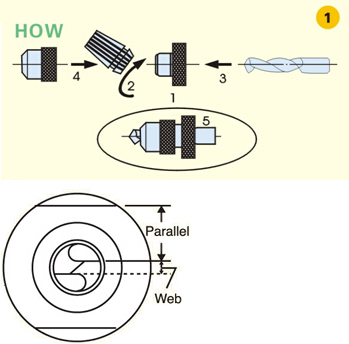

Ø Assemble the fixture (Fig 1)

Put drill, spring collect and the fixture parts together as the drawing steps 1 to 4.The group fixture is as step 5.

Ø Set the position of the drill bit (Fig 2)

Adjust the dial to the diameter of the drill bit, and then insert the fixture into the hole turn the right and lock it. Take it out and check if the drill bit and the spring collect are parallel. If not, do it again.

Ø Grind the point angle (Fig 3)

Start the machine and then insert the fixture into the sharpening hole (at side) until the bit point slightly touches the wheel. Then turn the fixture back and forth several times until the grinding sound disappears. Take it out and turn 180 degrees, do the same.

Ø Grind the lip relief angle (Fig 4)

Start the machine and then insert the fixture into the sharpening hole (at top) until the bit point slightly touches the wheel. Then turn the fixture back and forth several times until the grinding sound disappears. Take it out and turn 180 degrees, do the same

| Grinding Drill Dia | 3£¨2£©-13(15)mm |

| Point Angle | 90¡ã~135¡ã |

| Speed | 5300RPM |

| Voltage | 220V |

| Motor | 180W |

| Diamond wheel | CBN |

| Standard 11 collets (ER20) | §æ3, §æ4, §æ5, §æ6, §æ7, §æ8, §æ9, §æ10, §æ11, §æ12, §æ13 |

| Optional collets (ER20) | §æ2,§æ2.5, §æ3.5, §æ4.5, §æ5.5, §æ14, §æ15 |

| Optional collets holder | §¶15 collet holder |

| Wrench | 5mm Hex. Wrench |

| Weight | 10kgs Instruction |