Pneumatic Perfume capper Capping Machine

Structures and working principles

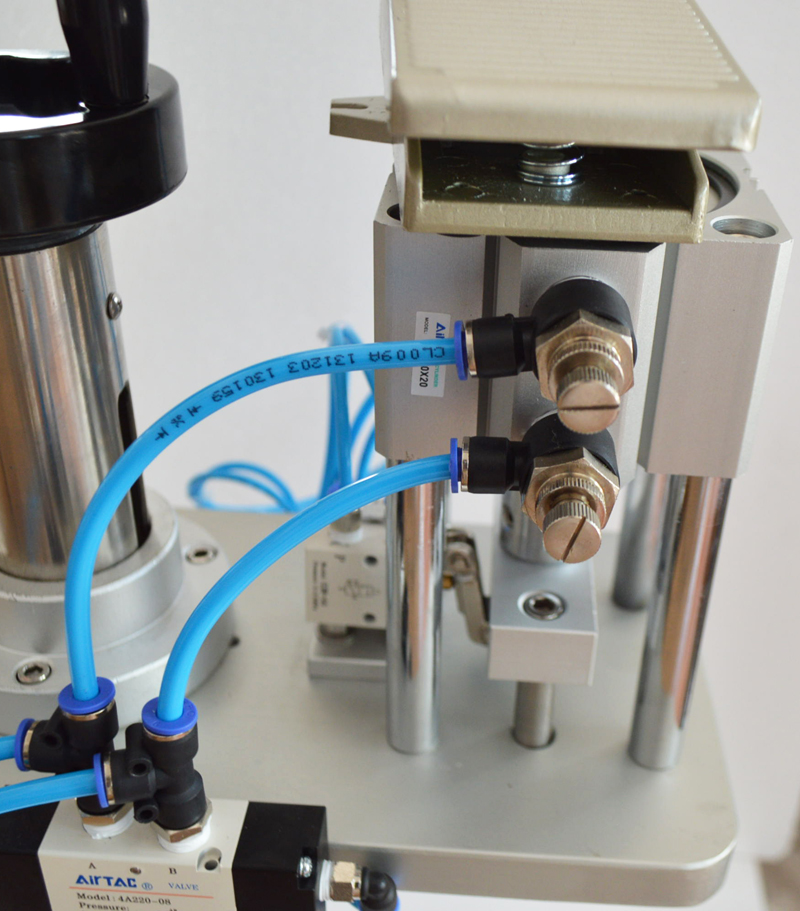

This machine is consist of two parts: sealing and air hole system. It adopts gas circuit once intercourse to finish a sealing operation with power producer by compressed air.

Sealing diameter: ¡Ó 13¡£ 15 ¡Ó17 18£®5 ¡Ó20 ¡Ó22

Working height: 60-200mm adjustable

Capacity: 800-1000bph

Accuracy: 99%

Machine size: 320*270*630

Weight: 20kg

A. Adjust the level of whole machine

B. Compressed air source leaded in machine air inlet by rubber hose, plug in, pull pipeline valve

C. Sealing operation adduction: according to operate food valve, adjust working height, make the catch-mouth parallel and valve plane parallel. When it is right, it can be used.

Maintenance and supply

A¡¢ Check the transition is smooth or not everyday, clean the air filter, air inlet everyday

B¡¢ Add grease once or twice a day in oil cup

C¡¢ Check gas circuit system connector

D¡¢ Check the sealing element of working parts, cylinder, material cylinder

E¡¢ Check the cylinder and air valve when it runs 1000-1500 hours

F¡¢ All components need to be cleaned and reassembled when it runs 2500 hours

1 Pneumatic Perfume capper Capping Machine £¨181009£©