|

|

新建网页 1

新建网页 1

新建网页 1

20140320

|

Salt

spray testing chamber 110V |

|

|

|

|

Voltage: 110V

Power:2000W

Laboratory volume: 270L

Inner size: 35.4*23.6*15.7 inch (900*600*400mm)

Outer size: 54.7*28.7*43.3inch (1390*730*1100mm)

Spray method: continuous

|

|

Features |

|

1.

Blunt material is required, it is required that the material itself cannot be

corroded, and it can not affect the corrosion test.

2.The fog nozzle cannot spray the test liquid directly to the sample , the

solution at the top of the spraying chamber cannot drop on the test piece.

3.The test liquid dropped from test piece cannot flow back to the salt bucket

again for the test.

4.The solution should not contain grease and dust, so you have to prepare an air

cleaner.

5. The level area of the spray taking device is 80 cm2, the diameter is about 10

cm. Put the spray taking device beside the test piece.

6.Spray liquid should be collected at least 16 hours, an average per hour can

be collected 2ml to 1ml solution. Use the final average to represent the amount

of spray.

7.The concentration of the Sodium Chloride Solution should be maintained at

40~60g/L.

8.The temperature of the pressure barrel should be kept in 47+1 degree,

temperature of the brine barrel should be kept in 35+1 degree.

The machine have timing function, and you could

set time to open or close automatically. |

|

|

Description:

|

Scope of application:

This product is used to test the corrosion resistance of the

electrodeposited coating of many kinds of metallic materials.

Use the salt spray test machine to spray the Sodium Chloride Solution to

the surface of electric coating to achieve the purpose of detection.

Best to calibrate the concentration once a day.

Test the PH value during experience after collection.

Continuously, cannot interrupt.

Collect once per hour, at least 16 hours, mean the average value.

Test at least twice a day, interval seven hours every time.

Other humidity required by the seller and the buyer agreement.

Continuous time from the beginning to the end.

|

|

Details:

|

|

|

|

Spray method:

|

|

Adopting

bernoute principle to absorb brine and then atomize, the degree of

atomization is even, no blocking phenomenon of crystallization, can

ensure the standard of continuous test.

Nozzles: made

of special glass nozzles, the size of the spray can be adjusted.

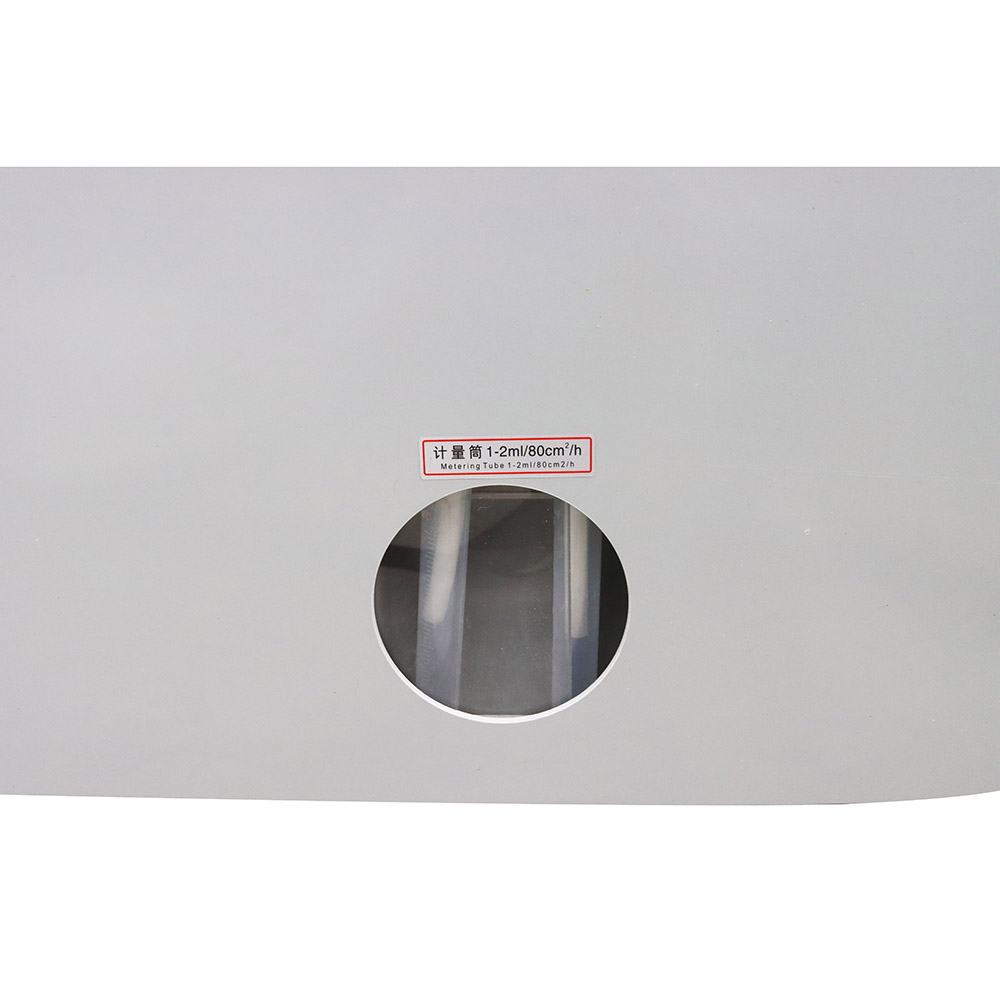

Spray flow rate

adjustment 1-2m1 (m1/8ocm'/nh) (16-hour average)

Spray mode:

continuous type

Adopt the

direct heating method, the heating speed is fast to reduce the standby

time, when the temperature reaches ON. OFF switching, accurate

temperature, less power consumption. (heating tube is made of high

corrosion resistance heating system: titanium tube).

Meet the standard:

| GB/T 2423. 17-1993 |

Salt spray test |

| GB/T 2423. 18-2000 |

Salt spray test |

| GB/T 10125-1997 |

Salt spray test |

| IEC68-2-52 1996 |

Salt spray test |

| ASTM. B117-97 |

Salt spray test |

| GB. 10587-89 |

Salt spray test |

| IEC68-2-11 |

Salt spray test |

| JIS H8502 |

Salt spray test |

| CNS. 4158 |

Salt spray test |

| CNS. 4159 CASS |

Accelerate the spray test of cupric acetate |

| GB/T 12967.3-91 CASS |

Accelerate the spray test of cupric acetate |

| GB/T 1771-2007 |

Neutral salt spray performance test of

paints and varnishes |

|

|

Item included(239366) : |

1*Salt spray testing chamber 110V

You can make order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after payments cleared.

Orders are processed from Monday-Friday; Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty period has expired, you can

still seek for service or technical support from us with low cost. |

|

|