Description

- Application: applied

to the industries of advertising making, stamps processing,hand

crafts,art crafts production and some special accurate instrument

apparatus processing.

- Characteristics:be

good at processing small precision instuments,multi-file speed

control,speed curve and a straight line independent contor.

- Processed products:stainless

steel chesst-brand,copper seal,jade seals, making on the working

piece, copper electrodes,punching moulds and thermos dies,etc.

- Feature: be good at

processing small precision instuments, easy to control,support G

code.

|

|

Easy But

Professional,See from the table to find the

Technical Parameters

|

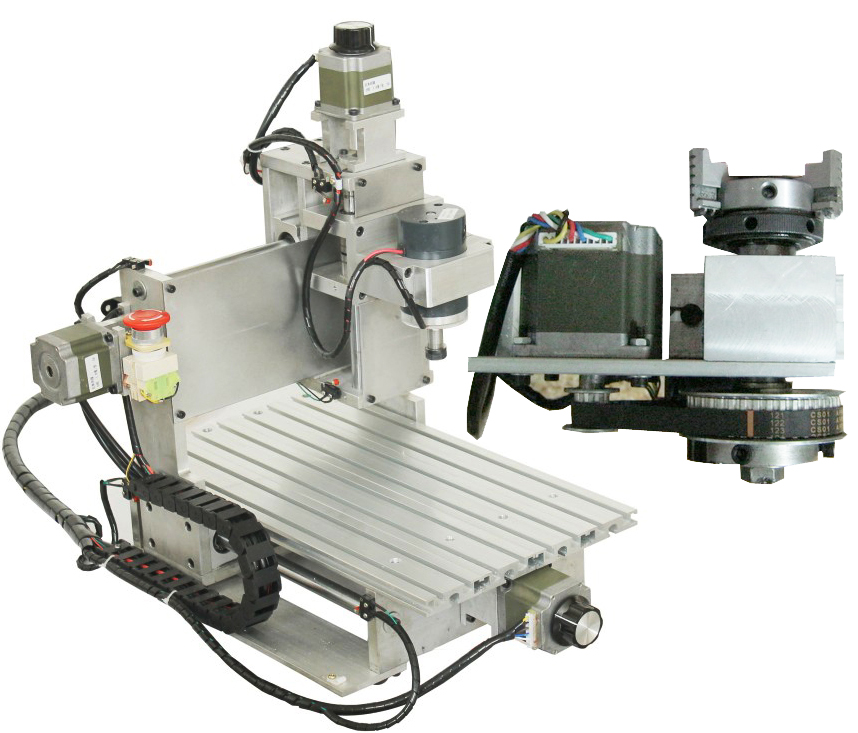

Effective working travel |

150(X)mm*220(Y)mm*100(Z)mm |

|

Max.workpiece dimension |

150mm*220mm*<70mm |

|

Work table dimension |

240mm*420mm*15mm |

|

Shape dimension |

300mm*470mm*500mm |

|

Frame materials |

aluminum alloy 6061 ,12mm |

|

Driving

units |

X axis |

1605 ball screws |

|

Y axis |

1605 ball screws |

|

Z axis |

1605 ball screws |

|

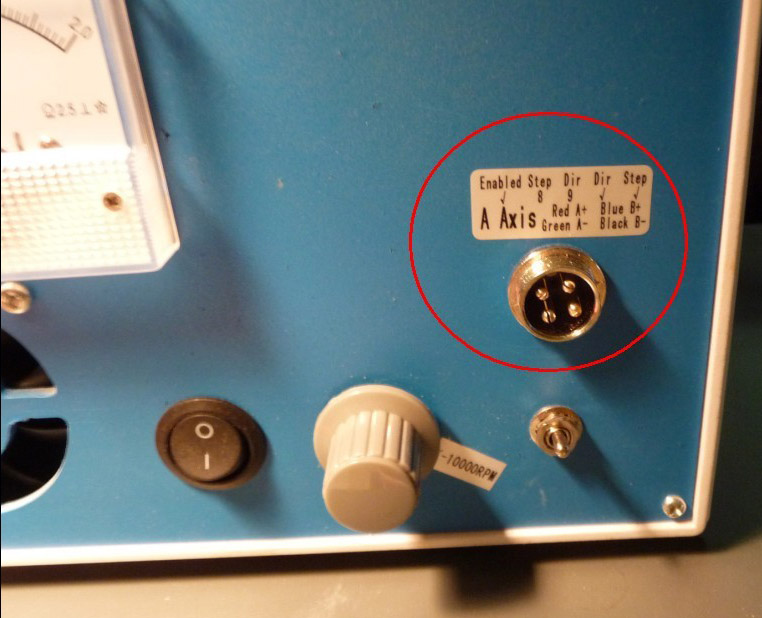

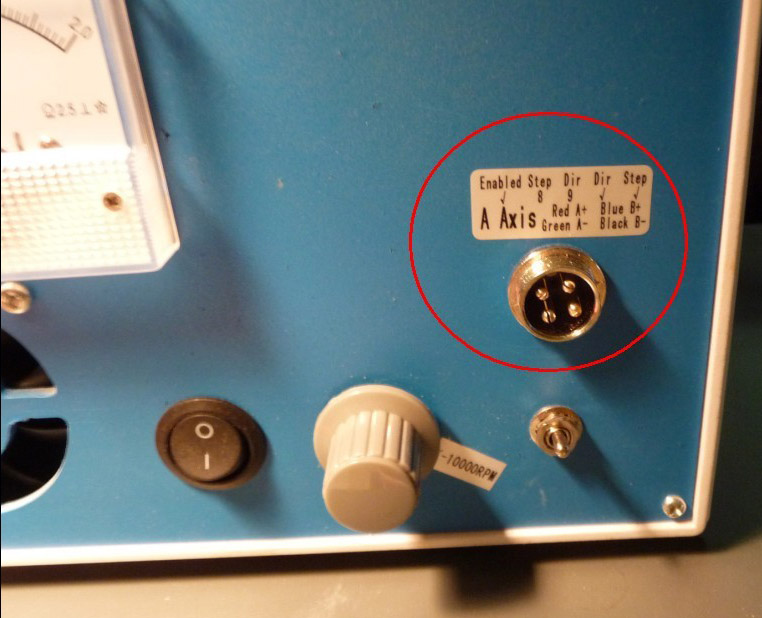

A axis |

10 teeth to 40 teeh Pulley Belt |

|

Stepping motor type |

two-phase 2-3A |

|

Spindle motor |

24V dc motor |

|

Principal axis collet |

ER11(6/3.175mm) |

|

Spindle speed |

3000 ~10000rpm/min (PWM stepless speed regulation) |

|

Repeat fixed position |

<0.01mm |

|

Spindle Shaft Runout |

<0.02mm |

|

Empty line speed |

0-2000mm/min (16 subdivided driving down) |

|

Spindle precision |

radial beat acuities 0.03 mm |

|

Control unit |

4xial one-piece drive + ring variable power + PWM speed |

|

Carving Instructions |

G code/TAP files/nc file/NCC files |

|

Communication interface |

through parallel connection with computer |

|

Software environment |

Windows xp /7 (32bits) |

|

Carving speed |

0-2000mm/min (different materials differ) |

|

Machine weight |

41kg (include wooden box) |

|

Protection |

Emergency stop button |

|

Control

box |

Operating Voltage |

AC110V |

|

Control unit |

2.5A stepping motor driver plus adjustable spindle speed

controller |

|

Computer connection |

on board palrallel port |

|

Command code |

G code |

|

Acceptable software |

Mach3 |

|

|

We

would offer the manual that shows how to set mach3 after purchasing,or

contact us for preview. |

| Why

choose us? |

|

Installation steps |

| |

|

|

|

START |

| |

|

↓ |

|

|

|

PREPARE

SOFTWARE & HARDWARE |

| |

|

↓ |

|

|

|

INTALL CNC

SOFTWARE |

| |

|

↓ |

|

|

|

INTALL

PAINTING SOFTWARE |

| |

|

↓ |

|

|

|

FINISH |

|

|

Customer: |

What are you selling? |

|

Seller: |

The package of the hardwares,mini

CNC ,control box and PCI_LPT card(PCI=>25

parallel port). |

|

Customer: |

Does it come with software? |

|

Seller: |

Yes.

we provide one-stop service. |

|

Customer: |

How can I get the painting

software? |

|

Seller: |

Because of the CNC software accept

G-code,We suggest customers to use Artcam 8.1 which can make tool path

into G-code.And the Artcam8.1 can be download from the home website for

preview. |

|

Customer: |

Can I use it with my PC?How can I connecte the

machine and computer? |

|

|

Seller: |

Yes.we offer a LPT_PCI card for the

computer that there is no parallel ports on the back of desktop

computer. It is easy to connect the cables according to guide . |

|

Customer: |

How do you ship? |

|

|

Seller: |

We ship it in a box as the picture

at the right side.We would ship it ASAP. |

|

Customer: |

Is it easy to learn and use? |

|

Seller: |

Yes,read the manual before starting

the machine,use it with a pair of glasses to protect your eyes,because

the Spindle runs in high speed. |

|

Customer: |

Where can I buy the tools? |

|

|

Seller: |

The engraving bits are sold in our

shop too. |

|

♥

Discover the Rewards of Owning A CNC

Router

Take a look at your options in the CNC

router market and decide if the potential rewards are worth the

financial investment. Is using computer technology to automate

control cutting, drilling and fabricating sign parts worth the

investment? Which table should I get? What software should I

use? CNC routers bring a laundry list of advantages to a growing

sign shop. Productivity is always a concern in a small business

and the ability to add new services, like 3-D engraving, is a

potential revenue generator. Greater quality and scaling

capabilities, of course, are critical. Add all these factors

together and the result could equal greater profitability for

your shop...

|

• Focusing on productivity |

• Getting a glimpse of the

market |

|

• Expanding your services |

• Examining all the options |

|

• Aiming for higher quality |

• Assessing price versus

features |

|

• Automating for

profitability |

• Getting the biggest bang

for your buck |

|

• Choosing a router that

fits your needs |

• Making the final decision |

|

• Sticking with the

industry standard |

♥

The whole story link:

http://www.signindustry.com/cnc/articles/2013-03-01-JL-CNCrouterProfitability.php3 |

|

Spindle

cooling fan

Notice 1:The

following pictures are taken in kind ,are not a network download(Many

other sellers copy pictures from website)

Wood

PCB

Metal

3D

creat

NOTICE 2:The

stability of spindle motor is the most important factor affecting the

effects of engraving, there are a lot of cheap machine is assembled by

cheap inferior material (you can have a look at their weight), and

their spindle is very inferior and easy to loose it will lead to

carving is very unstable, In order to improve the stability of the

spindle, we use the best materials, the most advanced technology and

the strongest structure, here's what we are doing the spindle jumping

experiments:

|

HR@E@SR3KON{V33V[}H.jpg)