Cushion Packaging Air Filling Bag Instruction

กก

Instruction

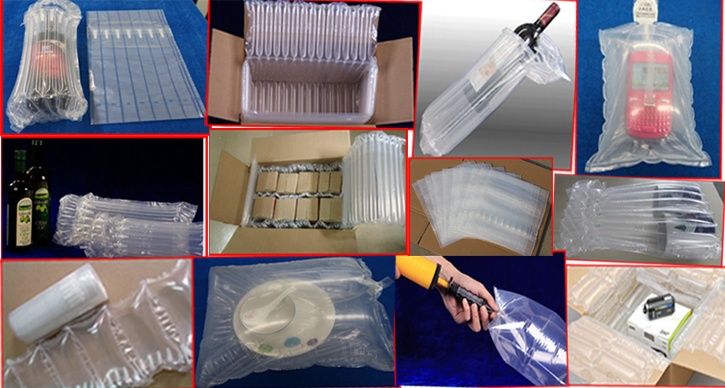

Cushion packaging

also known as shockproof packaging. It is the packaging that can slow

down the impact and shock of the contents inside and protect them from

damage. Cushion packaging is made of Low Density Polyethylene, and now

it has become a commonly used eco-friendly transparent flexible

packaging materials. It has

various kinds of

products, like filling bag, air bag cover, column bag and so on. It can

be used to wrap or ship different kinds of products.

Principle

The principle of cushion packaging is air

expansion. The products can be protected from shock and damage by air

full film, then the cushion packaging becomes an excellent buffer layer

between the goods and packaging. It fills the surplus space, absorbs the

shock and make sure the function of protection and buffering when the

products are shocked in the transport and moving process.

Application

Cushion packaging

has been used widely now. The main field of application is transport

packaging. It also can be used in the fields of luggage, handbags,

liquid product, electronics, circuit board, book, medicine, cosmetic,

instrument, ceramic, artware,

household electrical appliances, furniture, hardware products, glasswork

and precise instrument and so on. Almost all products can be protected

effectively by this air filling

cushion packaging.

Advantage and features

1. Instant and fast air filling,

safe

and airtight.

2.

Humanized automatic shape up function.

3. Light weight, good transparency, strong flexibility.

4. Sound insulation, no smell, no poison.

5. Humidity resistance and corrosion resistance.

6. Sturdy and durable, good air tightness.

7. Good

vibration absorbance, good resistance

to compression, good

electrical

insulation.

8. Highly energy/space/weight-saving.

9.

Can be

repeated use.

10.

Improve product image with modern fashion appearance.