|

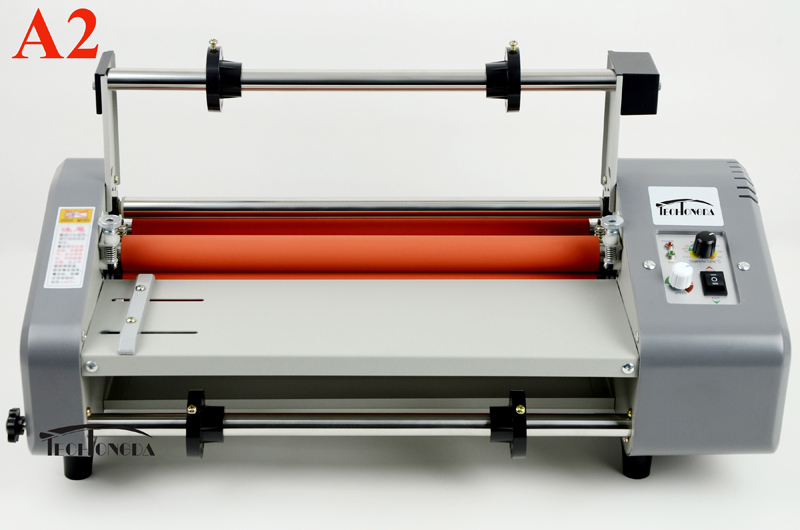

17.3"(440mm) Hot Cold Roll Laminator Kit |

|

120056:17.3in A2 Roll Laminator(110V) G-12 |

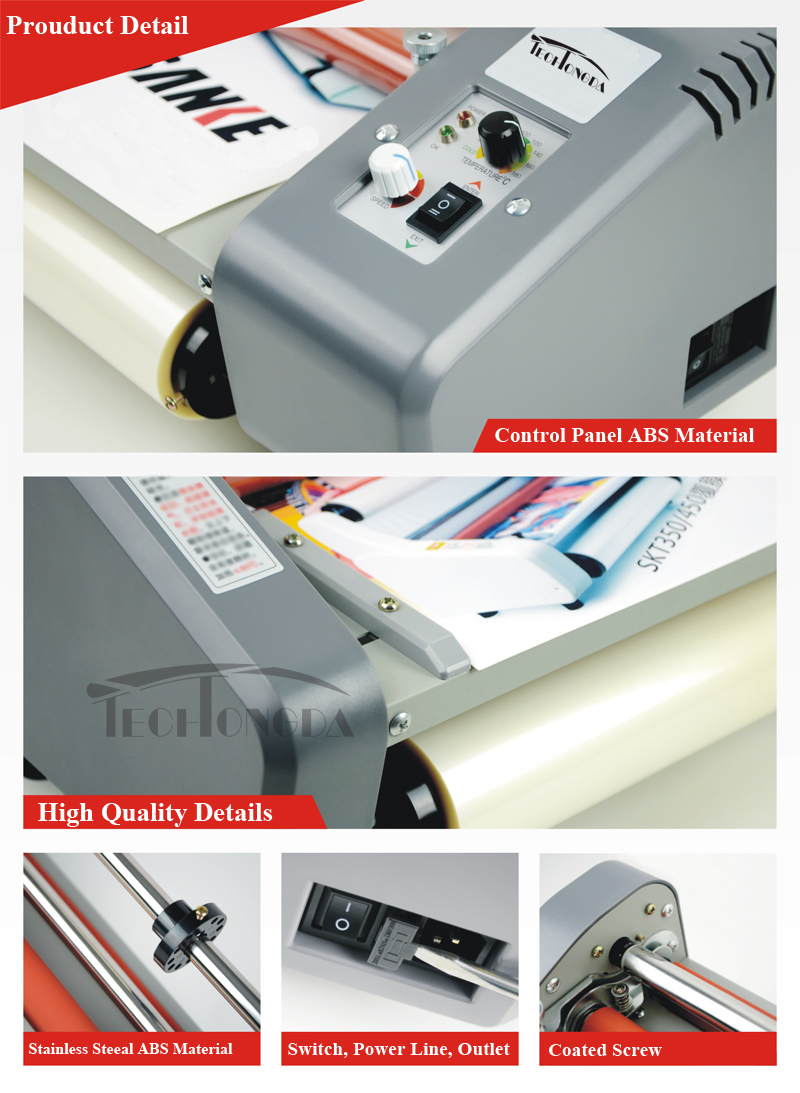

- Adjustable high speed laminating, 78.7In(2000mm) per minute

- Roller internal heating, high speed warm up and heating

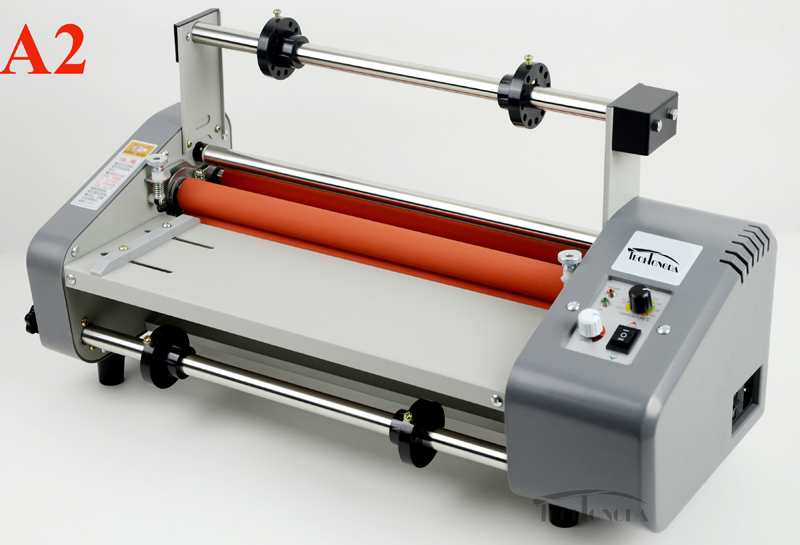

- Soft silicon big roller, well elastic, toughness, and durability

- Adjustable laminating thickness ,up to 0.2In(5mm)

- Economy in electricity :infrared radiation heating, warm up to 80 ¡æ for only 3 minutes

- Temperature adjustment, fit for different size and thickness of film

- The most popular laminating size:17.3"(440mm),suit for A2+.

- Dependability: Feeding paper smooth, no bubbles, reverse switch to make it safer

- Two laminating function, Hot&Cold laminating, roller heating

Specification:

|

Heating Method |

roller internal heating |

| Speed: |

variable, from 0- 78.7"(2000mm) per minute, 5 sheets / minute (A2 paper) |

| Maximum Laminating Width: | 440mm (A2 paper) |

| Maximum Laminating Length: | custom |

| Power Supply: | 110V, 50/60Hz (500W) |

| Warm Up Time | about 3 minutes |

| Temperature Control |

0-180¡ãC (32F-356F) (lamination film: within 100¡ãC-150¡ãC is recommended) |

| Materiel Thickness: | within 80g to 0.2" (5mm) thick paper |

| Package Weight: | approx 18.7Lb (8.5Kg) |

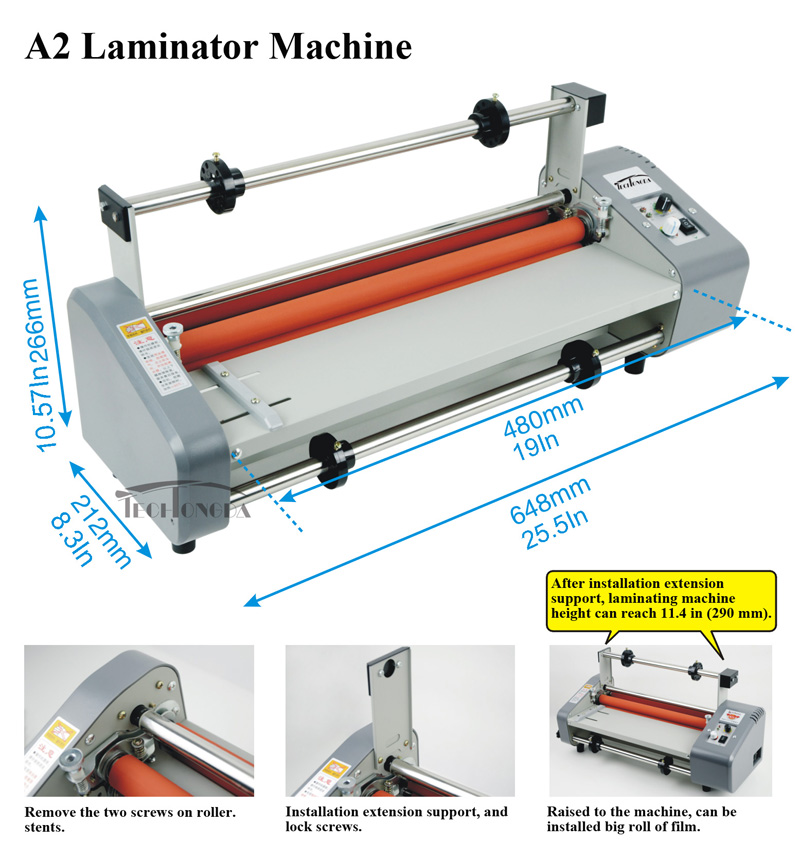

| Machine Dimensions (L¡ÁW¡ÁH): | 25.3" (645mm) ¡Á 9.8"(249mm) ¡Á 8"(210mm) |

1, Capable of subsequent processing such as coated by UV film, stamping press etc; Common laminating is not.

2, Can bend even fold, less to delamination; Common laminating is not.

3, Can write in ball-point pen on the surface if laminated by matt film; Common laminating is not.

4 Mainly applied to coating color spray paper, photo paper, uncoated paper and uneven art grain paper; common laminating is just applied to even uncoated paper

5, 3 type soft roll films: Glossy Matt and Pattern.

6, Fit for continues operation, enhance assembly effectiveness.

7, The supply cost is lower than common laminating.

8, With thermal glue, non-overflow after cold, product cut is clean and neat; Cold laminating is not, the cut will become black and dirty if the glue overflow.