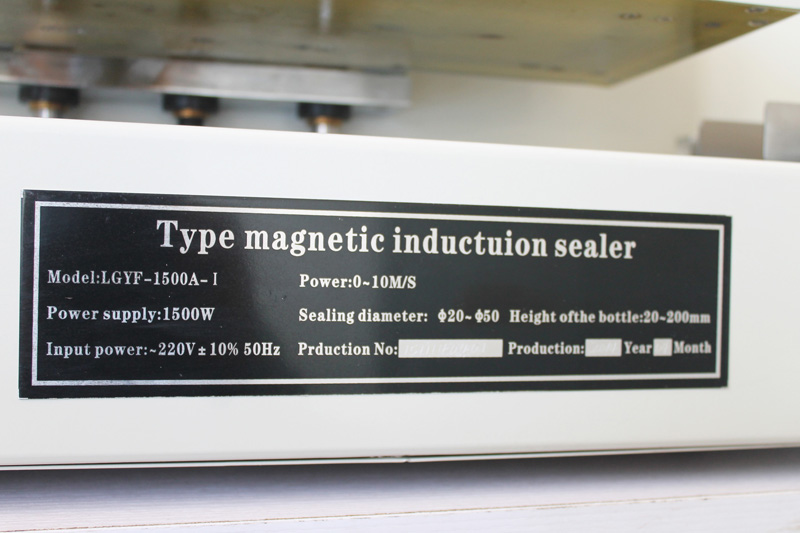

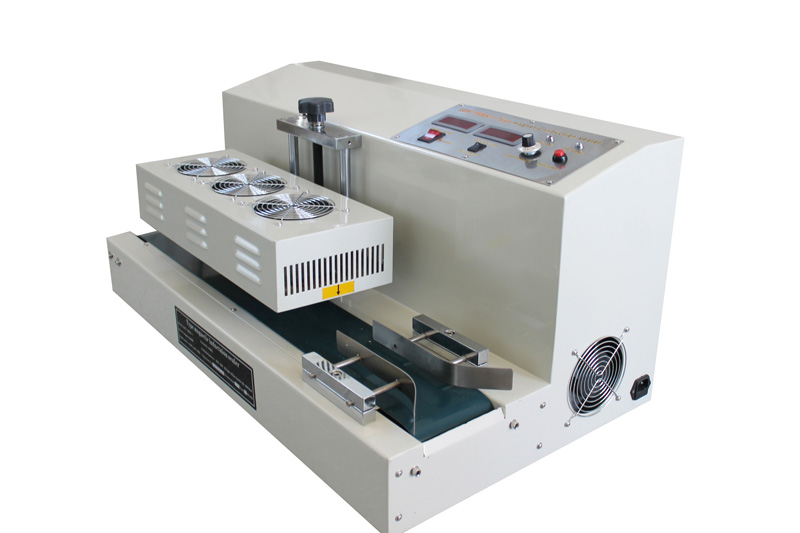

| The LGYF-1500A-I continuous induction sealer utilizes electro magnetic induction principle to produce instant high heat to melt aluminum foil to seal bottles. By sealing the bung hole you can achieve many things including preventing leaks, reducing spoilage, preventing tampering, and extending preservation time. Now it is widely used as sealing package machine in industries such as pharmaceuticals, pesticides, lubricants and cosmetics etc. | ||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

Parameters:

¡¡ |

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

|

||||||||||||||||

|

¡¡ |

||||||||||||||||

Induction Sealing: What Is It?The induction sealing process bonds a foil laminate inner seal to the lip of a container. After the container has been filled and capped with an induction-lined closure, it passes underneath the induction sealing system. The non-contact heating process welds the liner to the container creating a hermetic seal. The FDA regards induction sealing to be an effective method of tamper evidence. Why Choose Induction Sealing?When properly applied, induction lined caps provide a hermetic, leak proof, and tamper evident seal. Using an induction sealing system is ideal for extending product shelf life, preserving freshness, preventing costly leaks and enhancing your product's value. How Induction Sealing WorksAn induction sealing machine features two standard components: the power supply and sealing head. The sealing head consists of a coiled conductor covered by plastic housing. When the power supply energizes the inductive coil, it produces an electro magnetic current, called an eddy current. When a container fitted with an induction lined cap passes through this current, the foil from the inner-seal is heated. This melts the foil's outer polymer coating, which forms a bond with the lip of the container. |

||||||||||||||||

|

||||||||||||||||

|

||||||||||||||||

|

Items included(181033)

|