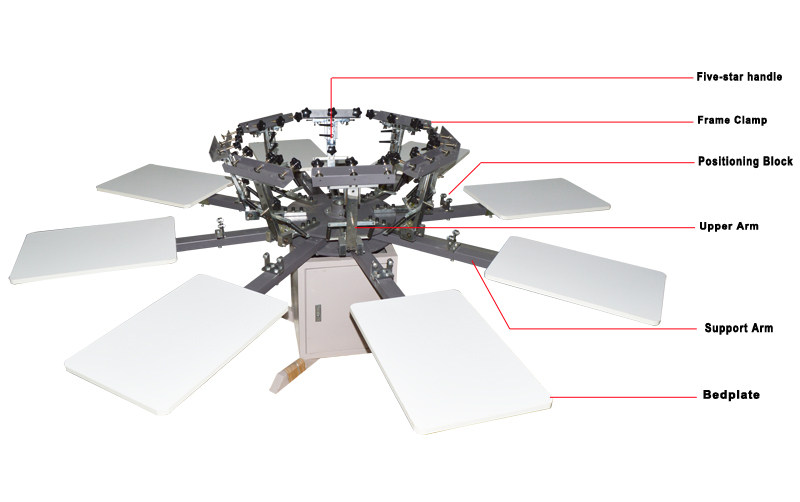

8 Color 8 Station Screen Printing Machine

1.Applicable Scope and Characteristics Features Characters

This machine is suitable for clothing overprinting. It is widely used to overprint T-shirts, clothing, backpacks, leather, cloth, towel and many other items. Cooperating with far infrared dryer can improve overprinting working effect. it is characterized by accurate positioning, saving room, saving labor and other advantages.

The screen can be trimmed forward and backward, up and down, left and right. When overprinting accurate exactly, conveniently and fast, the overprinting picture is clear and vivid.

1) Panel area (mm) Platen area: 400 x600

(mm) (Other specifications customizable)

2) Frame size (mm) Screen frame size: 450 x650 (mm)

3) Surface size (L*W*H) mm Shape size: 2100 x2100x1200 (mm)(6-screen

spec)

1) After opening the box,

check whether the rotating machine is broken or not, and the accessories

are all in readiness or not.

2) Use the equipped bolts to fix the under support arms onto the

underpaid rotating table according to the number mark. Do a little

fastening in case to adjust later.

3) Put the support arm on the positioning blocks of the under support

arm one by one. The upper arms have been

adjusted already before leaving the factory selling, and they cannot be

loosened. Use the 2 bearings on the under arm to fasten

tightly.

4) Put up all the upper arms and rotate them by 60¡ã. Then put down all

the upper arms one by one, and make sure all of them would fallen down

in the middle of the positioning blocks.

5) Repeat rotating like this by 360¡ã. Properly adjust the gradient of

next under arms, to make sure all upper arms smoothly locate into the

positioning blocks of the under arms. At the moment, fasten all the

bolts of under arms. Now the adjusting process is finished.

6) Use the equipped small screws to fasten the fixed frame of the bottom

of the bedplates on bottom.

7) Installing bedplate is fastened in the working position of under

arms. Fasten the net frame on the clamp. When putting down the screen

plate, it can match the area of the bedplate.

8) In the printing work, according to the overprinting requirement of

the pattern, you can adjust fine tuning handle, and it can achieve

specific printing effect. to make the printing accurately during the

work.

4.Usage Steps

1) Screen Installation

and Distance Adjustment.

The distance is about 5-10 mm.

Install screen frame on the clamp of the upper arms, then fasten it

tightly. Adjusting the five-star handle can adjust height. The five-star

handle can adjust left-and-right movement, and the effect of inclining

up and down, to make the distance between screens meet the printing

demand. When necessary, adjust the 4 M6 Allen screws on the back of the

net frame clamp of the which fixed net frame, and it can adjust and

fasten the net frame clamp. Use the 2 M8 fine tuning handle to do the

fine tuning function.

2) Overprinting Fix the product position

According to differences of overprinting products, you can stick or

paste on the bedplate, and set the substrates on the bedplate in order

to print easily.

3) Allocating dryer to improve the efficiency

When printing the products, wait until the ink is dry, then you can over

print. So you should allocate small dryer to can improve the efficiency

according to the specific condition. Adjust the properly allocated dryer

to 50-100 mm high above the bedplate, and according to the printing

speed and the demand for heat, choose the heating effect of the dryer.

Specific using method can be seen on the dryer introduction.

4) Pilot Printing

Put the upper arm which has equipped screen down in the middle of the 2

bearings on the positioning block and do single-color printing. Put up

the upper arm and rotate it by 60¡ã to certain direction, and make the

substrate under the dryer to heat. Put down the upper arm to print the

2nd next substrate, and put up the upper arm and rotate the underpaid

rotating table by 60¡ã to rotate the 2nd substrate to the next printing

station. Register Proofread the screen on this station. Repeat the steps

above and adjust the screen¡¯s distance. After registering proofreading

the screens, overprint next color and so on.

5) Printing

When the trying printing is accurate, formal printing can be started. If

the printed pattern has any deviation, do some proper adjustment to

overprint specifically.

Attention

As to improve the printing quality to get ideal print effect, when stretching the net to make the screen and printing, we advice to use unified aluminum alloy screen frame. The stretching tension of using the screen should get consistent.

|

|

Item# |

Description |

QTY |

Unit |

Note |

|

219009 |

¡¡8 Color 8 Station Screen Printing |

1 |

piece |

Screen Frame NOT included |