|

20" x 10ft

PU Vinyl

Transfer |

|

PU vinyl transfer is now the most

popular heat press material. PU vinyl can be cut by

a

vinyl cutter

to print name, number, logo and design on

T-shirts,

sports wear

and

other garments by

a heat press.

It is very durable,

stretchable,

washes fast and will last life of garments.Process the image

on your computer, cut the picture contour with cutter

plotter, then peel off the part you don’t need. At last,

press the image on T-shirt or other fabric products.

This listing is

for one 20"x10ft roll in one color.

Pick the color you

want and tell us your choice after payment.

|

-

Advanced

PU material, many varieties, different colors. The color

is bright and pure.

-

Recoverable feature. The base paper has a high

temperature resistant adhesive layer. If you make a

mistake and peel the image part off, just stick it back

to the base paper. Everything will be as it was. This is

useful when you cut small patterns and letters.

-

Apply to

all kinds of textile material (include the low

temperature press materials such as purified cotton and

non-woven fabrics). No color restriction of printing

stock, strong masking power. Wide ranges of use,

especially suitable for the heat press of athlete team

clothing, LOGO, single color image, garment accessories.

-

A very

prominent advantage of PU vinyl transfer is that it can

be finely engraved and one-step shape-forming. You can

press concolorous images of your idol or even your own

pictures on clothing, which is impracticable for other

materials.

-

Resistant

transfer, able to endure washing, can be washed by all

kinds of ways.

-

Suitable

for computer drawing past master to design very

personalized products.

|

Composition |

|

Ingredients |

Weight% |

|

Polyester film |

60.7% |

|

PU layer |

13.1% |

|

Polyester hot melt

adhesive |

26.2% |

|

|

|

|

|

|

|

|

Instruction of ASC PU Transfer |

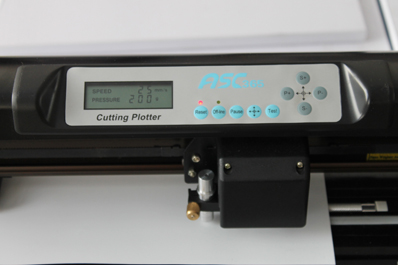

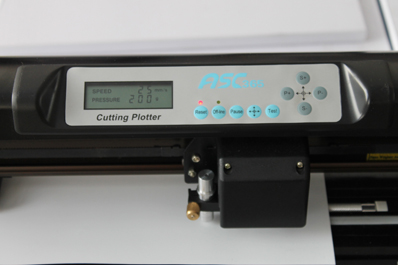

1) Make target

design by computers. Switch on the cutting plotter

and better try the pressure of tool in the first

step:

After cutting, the color layer as well as one layer

of base paper can be easily removed at the same

time. |

2) The tool should

just cut half thickness of the base paper.

|

3)Set the speed

according to the size of the design. For example,

set the speed faster (at 50-75) for a large design,

and at 25definitely for a small one. Pressure is

about 150g.Lowerspeed cutting is very important! |

4)You also can cut

the design on PU vinyl By graver

|

5)Peel off the

unwanted color layer part when finish cutting.

|

6)The design on

base paper should be complete without any deletion.

If you peel the wanted parts ,you can press it back

then continue. |

7)Press by heat

press, Set the temperature at 150℃-175℃(310F-350F)

and the time at 10s -15s.

The temperature & time is not absolute, You should

adjust on actual status. |

8)Press by home

Iron. Set the temperature at 150℃-175℃(310F-350F).

|

9)Cool peel the

base paper. |

10)A wanted design

will be on your unique T-shirt completely. |

|

|