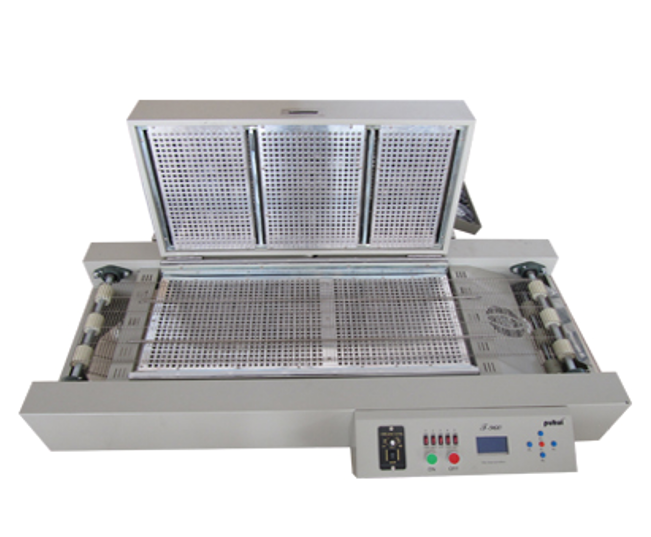

LED SMT Reflow Oven T-960e 220V

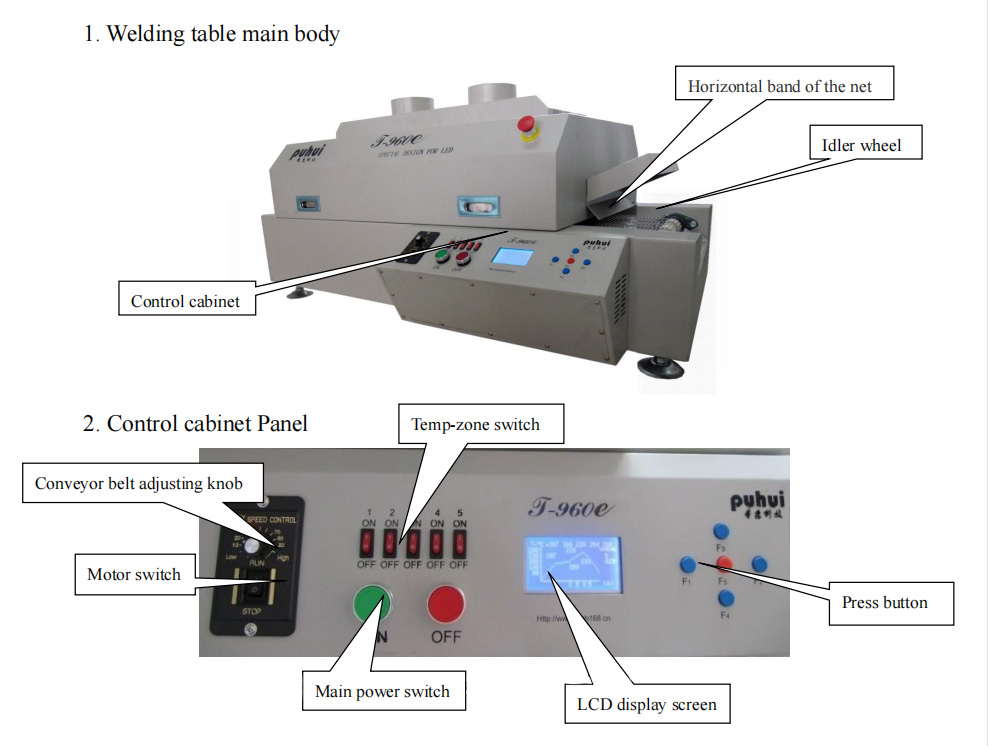

2. This machine is equipped with the crawler-type and five temperature zone heating systems, and each temperature zone uses independent PID controlling and up-down heating type, can make the inside temperature more accurate and well-proportioned, just take about 20 minutes can let it heat up to the working temperature from the room temperature.

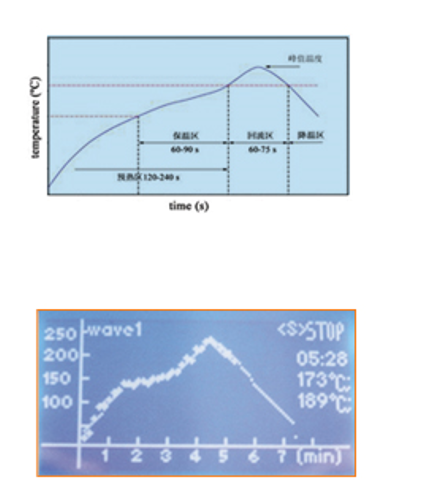

3. Intelligent temperature wave heating type, oversized capacity wave selection, have eight temperature waves can satisfy various welding technological requirements.

4. Use programmable technology, preset the temperature wave memory storage function, can complete the whole welding process automatically according to your presetting wave.

5. Adopt the thermocouple temperature measurement and add the compensation circuit, make the temperature measurement more accurate, the wave more perfect.

6. Use PID intelligent temperature control technology; make the temperature control more accurately. Adopt the imported large current solid-state relay non-contact output can effectively avoid the IC or circuit board damage due to the rapid or uninterrupted warming up, make the whole welding process more scientific safety.

7.Transmission system adopt imported frequency conversion motor, PID closed-loop speed, equip with all the import 1:150 turbine speed reducer, smooth operation, speed adjustable range 0-1600mm/min.

8. Adopt independent wheel structure and special stainless steel strut, durable wear-resisting runs smoothly, speed precision can reach ±10mm/min.

9. Independent cooling zone, to ensure the PCB board of low temperature when the required.

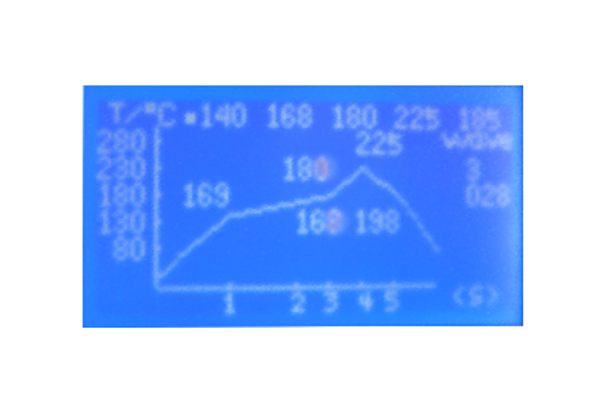

10. Friendly human-machine operation interface, perfect LCD display, no need to connect with the PC, can watch the whole repairing process very clearly.

11. Ergonomic design, practical and easily operated. Good build quality but at the same time light weight and a small footprint allows the T-960e to be easily bench positioned, transported or stored.

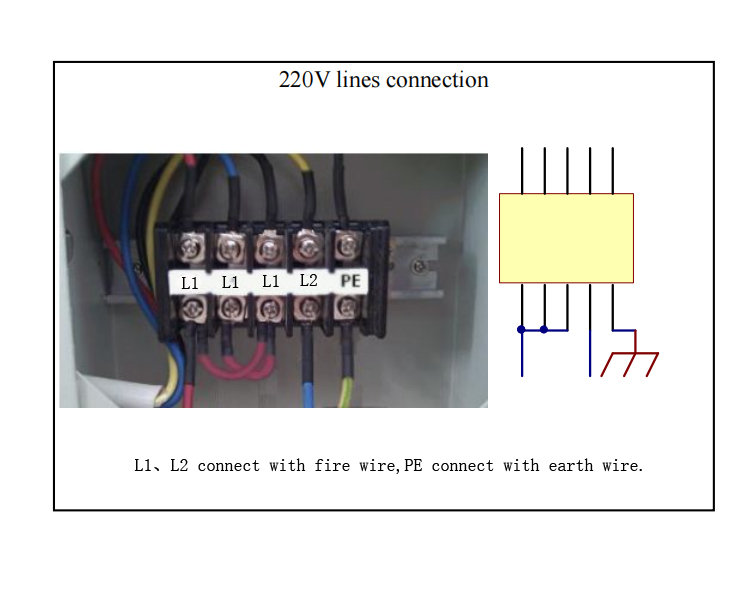

L1、L2-Firewire PE- Earth wire

NOTE:Customers need to prepare at least six square millimeters of power cables themselves.

1.Front-loadoperation

Outside-load operation panel avoids highlytemperature in the panel to improve stability.

2.eight waves can be preset and memory

a.Use programmable technology,preset the temperature wavestorage,can complete the whole soldering process automaticallyaccording to your preseting wave.

b.Easy operation,8 waves satisfy various soldering technologicalrequirements,avoid to change temperature every time.

3.LCD display intuitive

LCD display intuitive every data.

4.PID temperature control system

PID temperature control system,temperaturesetting is convenient,high precision oftemperature control,lower-power,highlyproduction efficiency.

5.Heating insulation laver in tank for insulation

Heating insulation layer in tank for insulation to keep temperaturestability of six zones.

2. Do not put

the machine near the electromagnetism interfering resource.

3. Do not put the oven exits and entrances face towards to the fan and

the window

2. Do not use and store the machine out of door, high temperature and humid condition.

3. During operation take care of the high temperature, avoid scald.

4. When overhaul the machine, please cut off the power supply to avoid electric shock or cause short circuit.

5. If move the machine after overhaul, must check all the parts, especially the net-belt position. Cannot make it be lock or fall off.

6. Ensure the machine is stable, not lean or instable. Adjust the leg under the machine to keep the transmission horizontal. Or the PCB will shift in the transmit process.

7. Do not put too big and big absorbed heat components into the oven avoiding damage the net-net and affect the temperature.

8. Put lubricating oil into the transmission chain every 7 days.

9. Do not put the inflammable and explosive dangerous goods near the reflow oven.

10. Do not reach hands into the reflow oven when the machine is in normal working condition.

2. Check the fan shaft sleeve is in good condition.

3. Check the fan and the electro-motor have abnormal sound.

4. Be sure the fan does work flexibly.

5. Check the air hole if there are abnormal materials.

6. Check the transmission net-belt is in good condition.

7. Check the electrical chest and electrical equipment have abnormal sound.

8. Check the transmission part if it is in good condition and has abnormal sound.

9. Before turn on the machine, please check the working voltage if it is in the safe voltage and if it is stable. Ensure all the parts can work safely and normally. At the same time, when turn on the machine, check the parameters are the same to the last time turn off. When turn off the machine, do not let the transmission belt in the hot area, please turn off the temperature and when cool down well and stop the transmission belt.

10. Lubricate the driving rolls. Put lubricating oil every two months.

11. The motor works in high temperature for long time, please put lubricating oil twice a week or more, ensure the motor can work normally.

12. Clean the residual goods on the fan blade and motor timely. Or the circuit ages will lead to short circuit and damage the fan.

13. Be sure the machine contacts the earth when use five-wire system.

You can make

order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.