Special designs:

1) Safety board: When touched by hands or other subjects it will immediately stop and make alert sounds, the screen will show number: E7 , the lower mold will retrieve automatically to avoid hand-cutting.

2):When deal with cups of different depth, it could adjust itself automatically.

3):Automatic detection: The circuit board can detect the location of the error and point it out on screen.

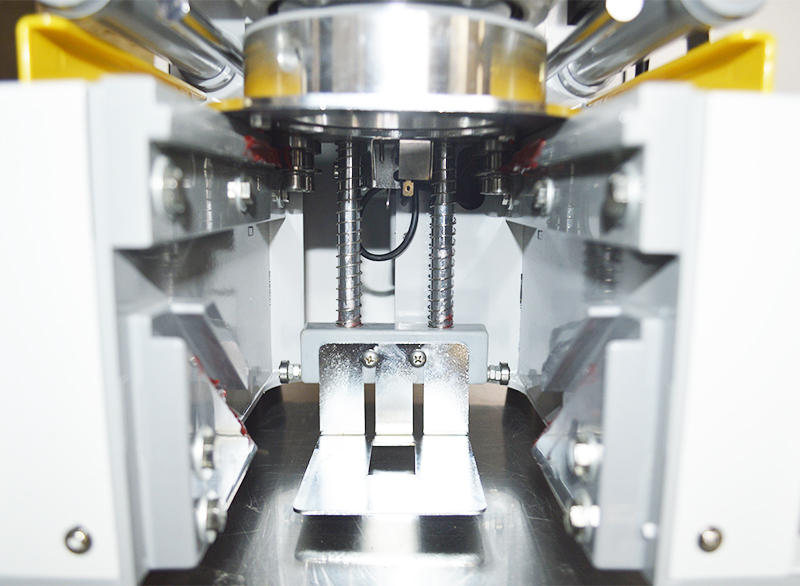

1st put the cup into the cup mold.

2nd it will be retrieved automatically(or manually) and sealed.

3rd the upper mold will press down and cut the membrane.

4th the cup mold comes out.

5th the membrane retrieving rolls start turning.

6th get your sealed cup.

Instructions:

Before operation:

1) Set the membrane as shown or the sealing will not be tight.And make the electric eye target its position.

2) Press POWER, the cup mold will come out and the sealing part starts to heating.

3) AFTER 5-7 MINS, when the sealing part’s heating process is over the heating light will be off and it means it’s ready for work.

4) The membrane must match the material of the cup. For example. PP membrane for PP-covered cups.(The heating temperature is default 239-329 or 329-365°F.

5) When work is done, PRESS THE POWER BUTTON BEFORE PULL OUT THE PLUG.

6) DO NOT PUT YOUR HAND INTO THE MACHINE AT ANY TIME!!

7) Make sure press the power button after you insert the plug, when the screen is on, it means the sealer is standby.

8) Use ▲ and ▼ to set numbers. Press the Counter button and it will clear all the number of cups.

9) Left window for sealed-cup numbers and the right for heating temperature.