|

|

Metallographic Sample Polishing Machine 220V |

|

|

Usage |

|

Polishing is an important procedure during

metallographic sample preparation, by the polishing machine you can get

glassy surface on your specimen.

It features stable rotation, low noise,

convenient operating and high working efficiency.

It is perfect for factory, research unit

and metallographic lab.

|

|

Technical Specifications |

Polishing disk: dia. 200mm

Rotating speed: 1400rpm

Motor: 220V, single phase, 50HZ

Net weight: 33LBS./15kg |

|

Brief introduction of

structure and performance |

1. The motor is fixed on the machine

shell by fixing plate.

2. Polishing disk is fixed on the main shaft of motor by taper sleeve.

3. Aluminum ring buttons the polishing textile on the polishing disk.

4. Start motor, the motor torque is transferred by cone screw of taper

sleeve.

5. During polishing the splash liquid is blocked by splash guard and

drained by outlet pipe.

6. During non-using, please cover by dustproof cover, to avoid dust and

other impurity to fall in the polishing textile to affect the polishing

effect. |

|

Installation and operating

rules |

|

1. Open the plywood case, move off the V

shape cushion under the machine and adhesive tape fastening dustproof

cover.

2. Place the machine in the indoor circumstance without powder and

vibration.

3. Take off the dustproof cover, splash guard and aluminum ring.

4. Place the wet and neat polishing textile on the polishing disk.

5. Fastening the ring on the disk.

6. Place the container on the outlet pipe to take in the waste solution.

7. Plug in the electrical source, turn the switch in “on” position to

start motor, now polishing task can be processed. |

|

Maintenance and operating

safety rules |

1.During polishing, too big load on

the specimen is not allowed, for it will tear the polishing textile and

cause the motor in overload situation.

2.The maximum temperature raising of motor is not beyond 80 degree.

3.Earth line of plug should be connected well.

4.Polishing textile should cling on the disk, broken textile is not

allowed use, or it will cause danger of specimen fly off.

5.Carefully using the machine under minus 10 degree circumstance to

avoid break the plastic parts of the machine.

6.After long time using, motor high speed lubricating oil should be

replaced in time. |

|

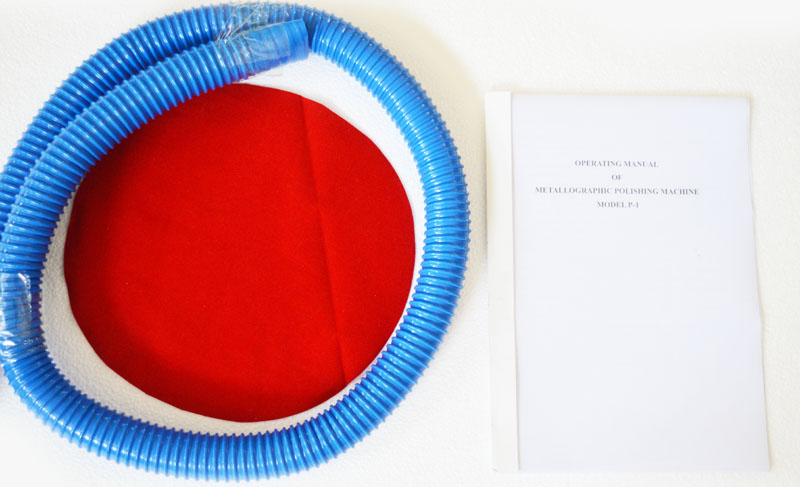

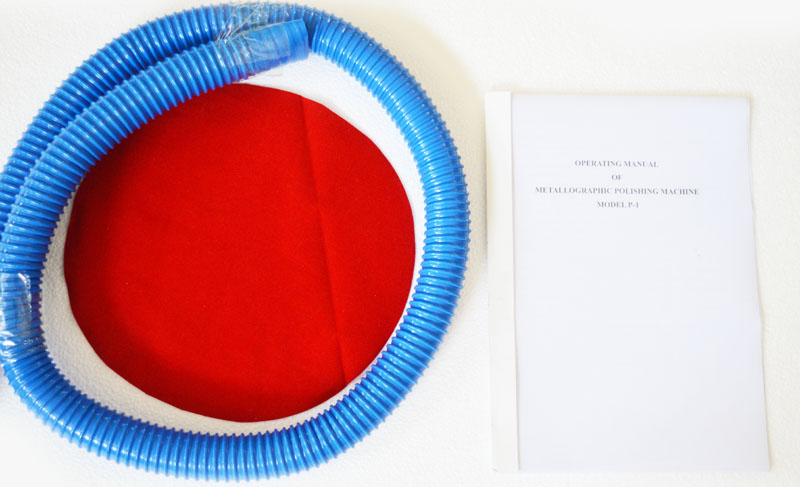

Product Show |

|

|

|

|

|

|

|

Item Included |

Metallographic Sample Polishing

Machine 220V(032167)

|

|

Item Number |

Description |

QTY |

Unit |

Note |

| 032167 |

Metallographic

Sample Polishing Machine 220V |

1 |

set |

Voltage: 220V |

|