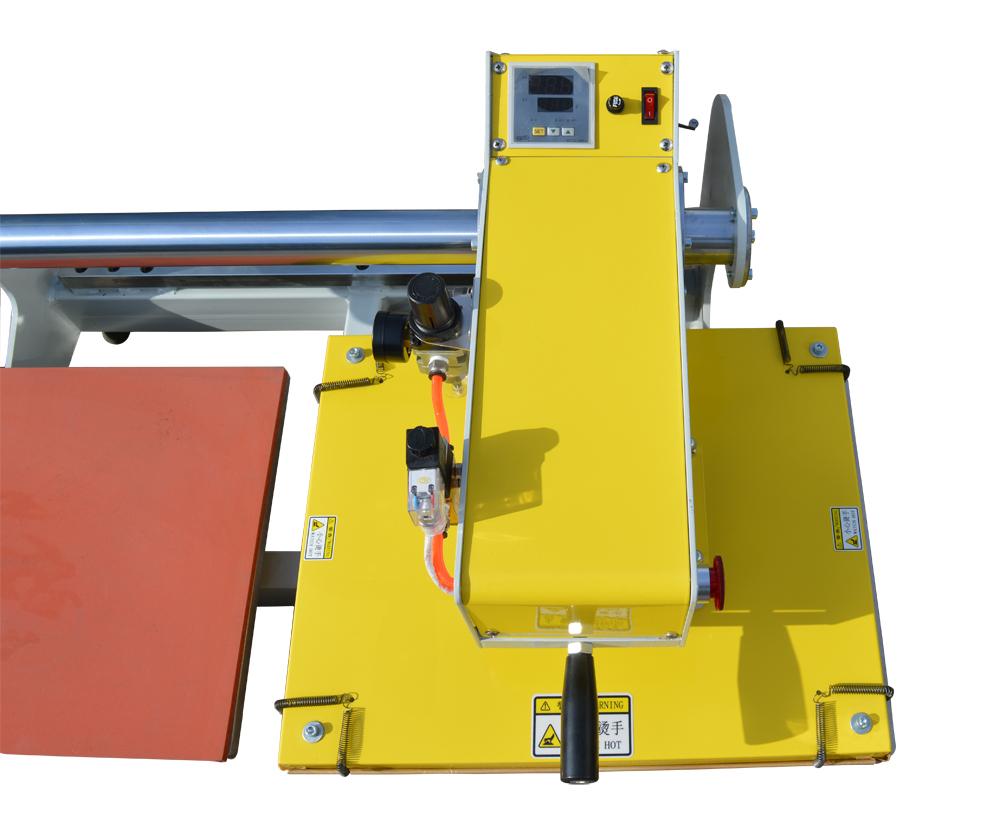

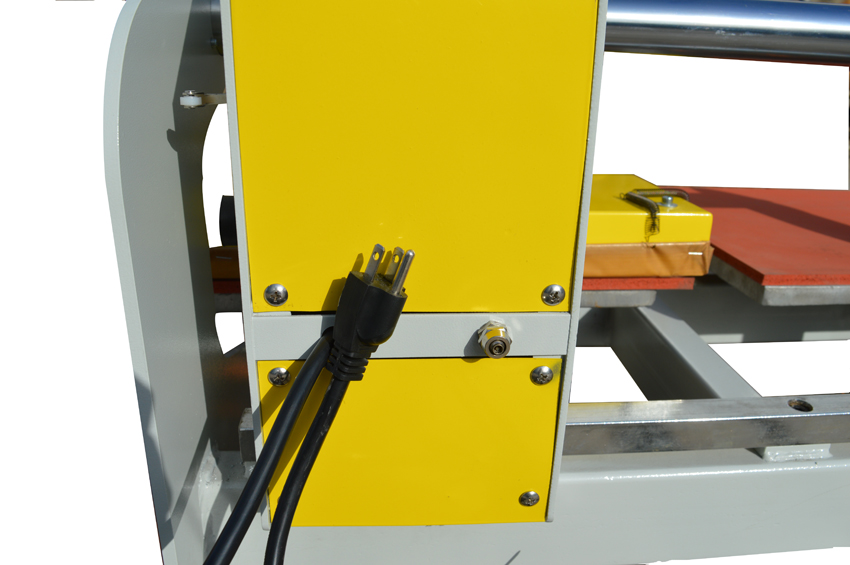

Double Station Pneumatic Heat Press Machine 16"*20"

This Pneumatic Double Table Heat press machine

is featured by its two working tables and air

automatic working system. The upper heating

board moves automatically and easily. It is very

efficient for advertising use and industry use.

Heating panel and working tables are specially

processed and make the machine works well and

tranfer images clearly. It's suitable for

sublimation and heat transfer printing work.

With CE certification and 12 months warranty!

|

Items |

Double-position Heat Transfer Printing Machine(Pneumatic) |

|

Model |

DJ-H402 |

|

Printing Area(mm) |

400*500mm(15.7*19.7inch) |

|

Temp.range |

0-399°C |

|

Time Range(s�/font> |

0-99 |

|

Votage/Power |

110V/3KW |

|

N.W.(kgs) |

110(50lb) |

|

Machine Dimensions(mm) |

1100*700*550(44*27.5*21.6inch) |

|

Packing Size (mm) |

1180*730*580(46.5*29*23inch) |

- CE approved heat press machine. high quality as well as good price, good after-sale service.

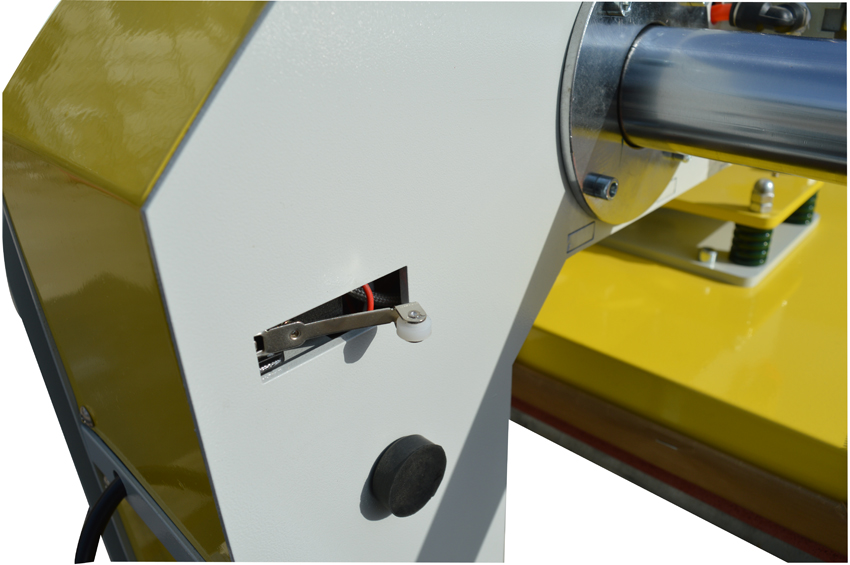

- The machine adopted automatic pneumatic fitting pressure, it can transfer the lower pressure to higher compress pressure. (pressure up to 8kg/cm2).

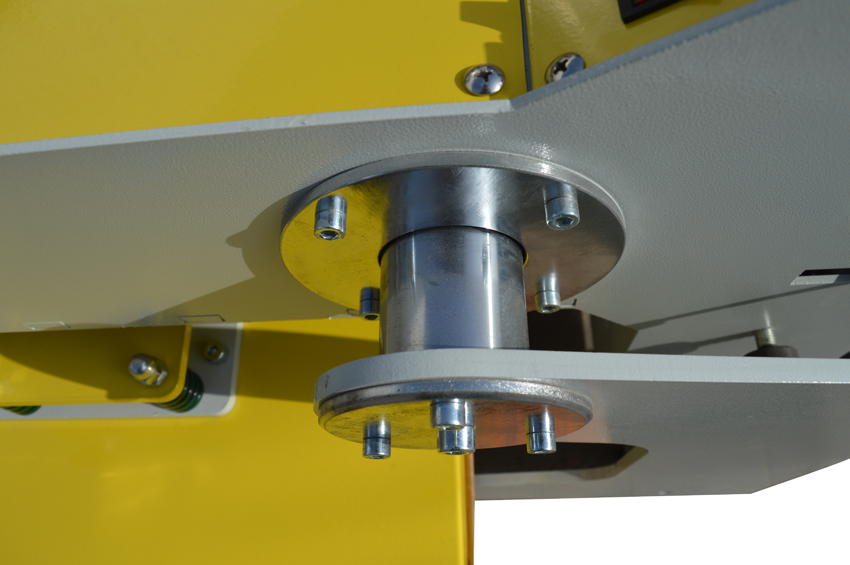

- It contains two locations, paralleled moving the head up left and right, much more convenient and faster, high efficiency ,save labor and time at one time.

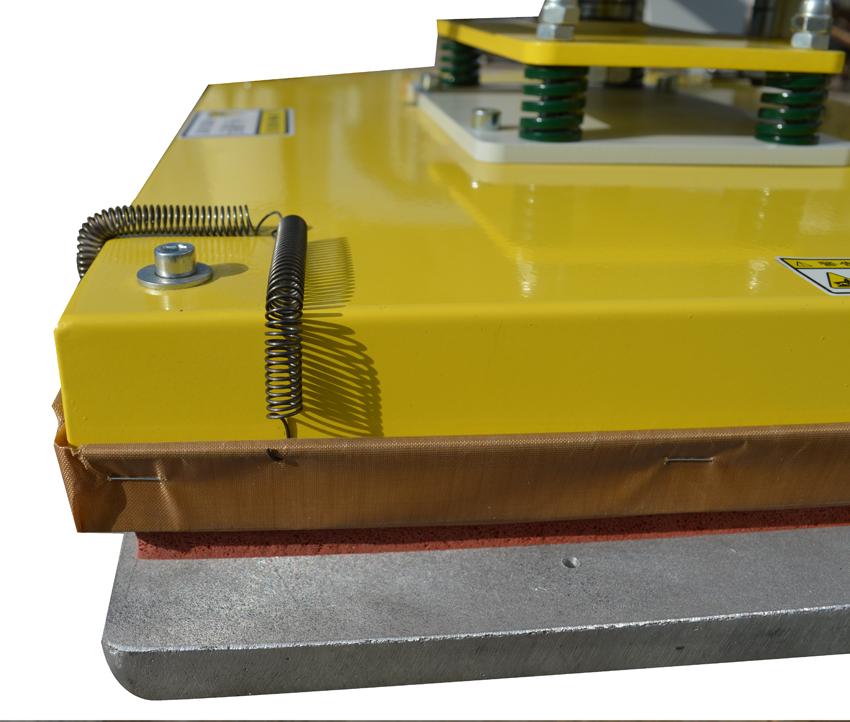

- This machine adopts thicken heat plate to ensure the temperature more equality and steady as to improve the transfer quality and avoids tolerance. high accuracy, perfect heat press effect

- Upgraded lower platen allows room for T-shirts to be easily, placed into and removed from machine, 10cm adjustable range, produce wider products

- The pressure can be adjusted according to the thickness of the material you're transfering to. Including print the ready made clothes and cut pieces ,it can be widely used in the factory mass-production and personalized pyrograph of retail shops.