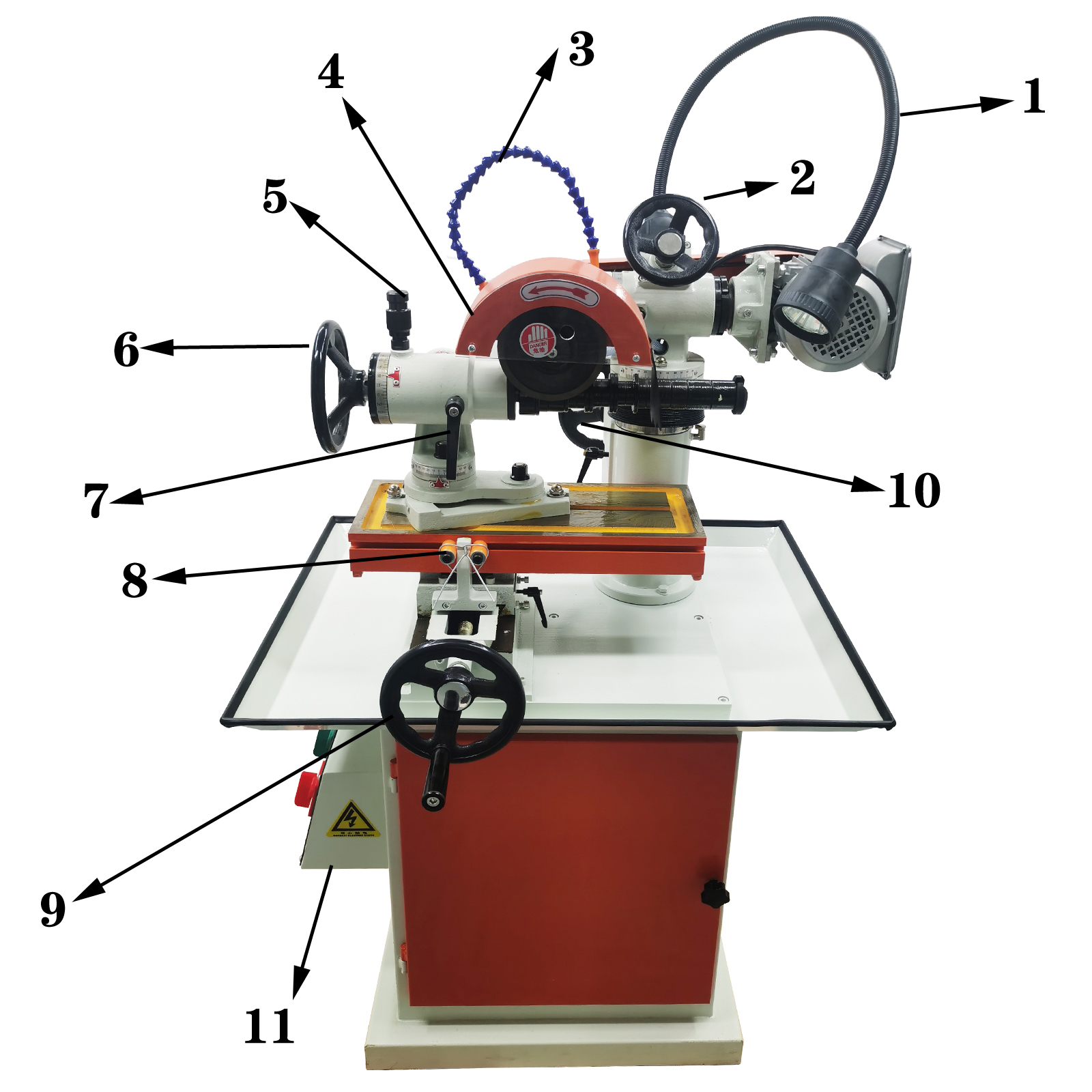

Universal Cutter Grinder 220V

1.Work light

2.Spindle angle adjustment handwheel

3.Water outlet pipe

4.Grinding wheel guard

5.Indexing locator

6.Tool holder adjustment handwheel

7.Knife holder locking handle

8.Workbench locator

9.Drag plate adjustment handwheel

10.Spindle lifting handwheel

11.Control electric box

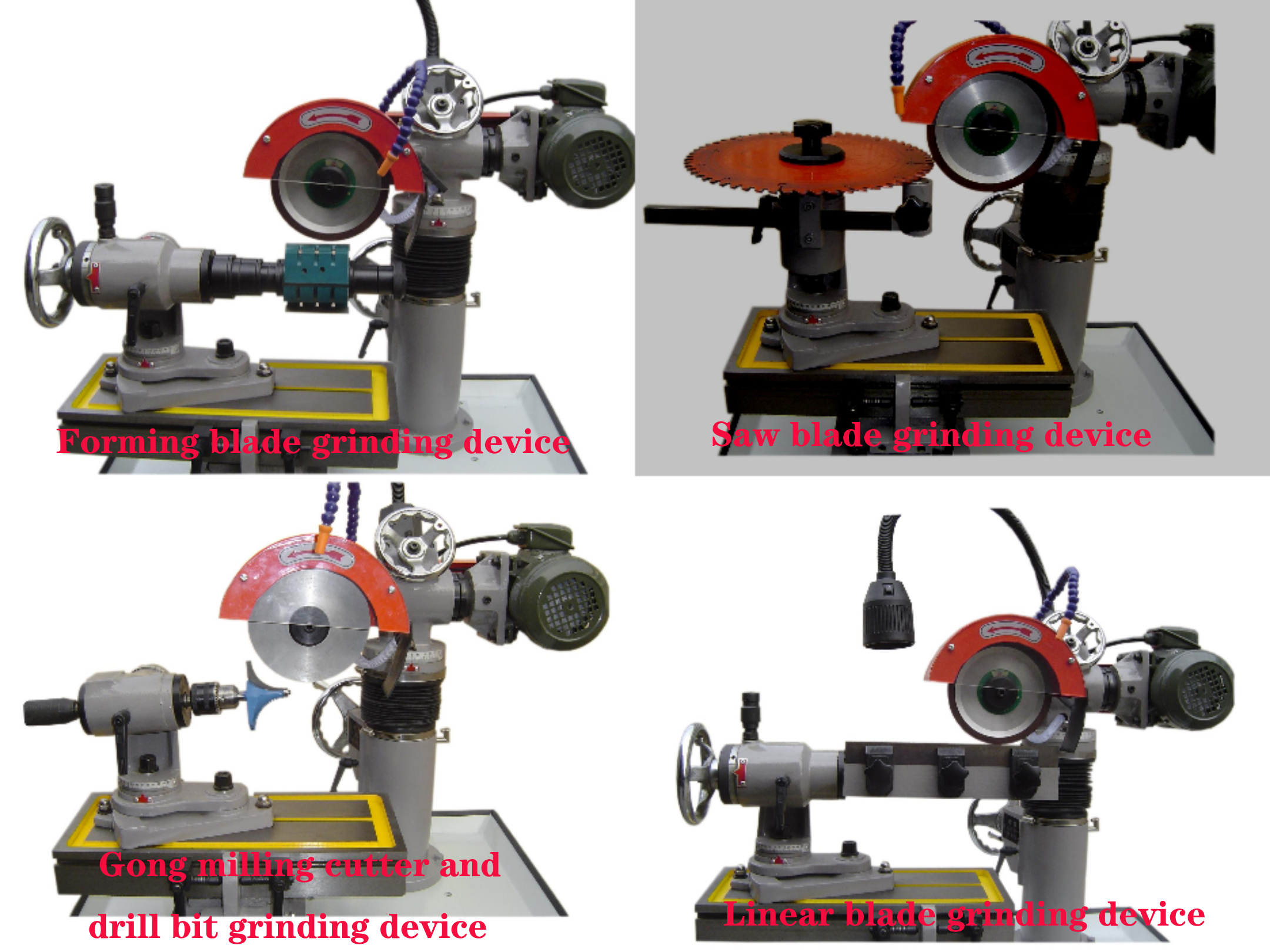

1.Operation method for shaping blade grinding

a.Loosen the locking screw of the tool shaft, remove the tool spacer, select the appropriate spacer, and insert the required sharpened tool onto the tool shaft. Tighten the screw to secure the tool.

b.Loosen the positioning sliding screws on the left and right sides of the workbench, adjust to the desired position, and then lock the positioning screws. Release the locking handle of the tool holder shaft, adjust the tool holder seat to maintain the correct pitch angle and left right angle between the tool and the grinding wheel, and ensure that the blade surface is parallel to the grinding wheel surface before locking the wrench.

c.The distance between the cutting tool and the grinding wheel is adjusted by the lifting handwheel of the grinding wheel. After the angle and distance of each part are adjusted, the workbench can be pushed to grind the grinding angle of the cutting tool.

d.When replacing one side of the tool with the other after grinding, release the locking handle of the tool holder shaft, rotate the index handwheel, switch to the desired angle, and then lock the tool holder shaft to grind the other blade.

2.Operation method for grinding circular saw blades

a.Remove the tool holder shaft and install the equipped circular saw blade sharpenerdevice.

b.According to the size of the saw blade diameter, adjust the saw blade diameter to adjust the sliding rod to the appropriate position, and then release the locking handle of the locator to adjust the locator to the appropriate height.

c.Move the position of the drag plate, loosen the angle adjustment screw of the grinding wheel, adjust the required angle between the grinding wheel and the saw blade, align the alloy profile of the saw blade with the plane of the grinding wheel, and then tighten the angle adjustment screw.

d.Rotate the lifting handwheel of the grinding wheel to align the center of the grinding wheel with the plane of the saw blade, and push the workbench to grind the circular saw blade.

3.The operation method of grinding the gong milling cutter and drill bit

Replace the equipped gong-milling blade grinding device, install the grinding wheel upside down and tighten the screws, rotate the grinding wheel lifting handwheel and adjust the position of the drag plate to make the gong-milling blade surface fit the grinding wheel, and then adjust the position of the stroke positioning block. If there is a special tool that needs to swing the tool holder angle, loosen the screw behind the adjustment seat and adjust it to the desired angle to grind.

4.The grinding operation method of linear knives

a.Install the equipped linear tool holder on the tool holder shaft, place the blade on the fixture, and lock the locking handle of the blade pressing plate.

b.Rotate the spindle lifting handwheel, adjust the distance between the blade and the grinding wheel, and then adjust the drag plate and tool holder axis to make the grinding wheel and the blade form a flat surface.

c.Rotate the indexing locator handwheel, adjust the angle of the required sharpening tool, lock the tool holder screws, and then adjust the position of the stroke positioning slider according to the length of the processed blade. Push the workbench to grind.

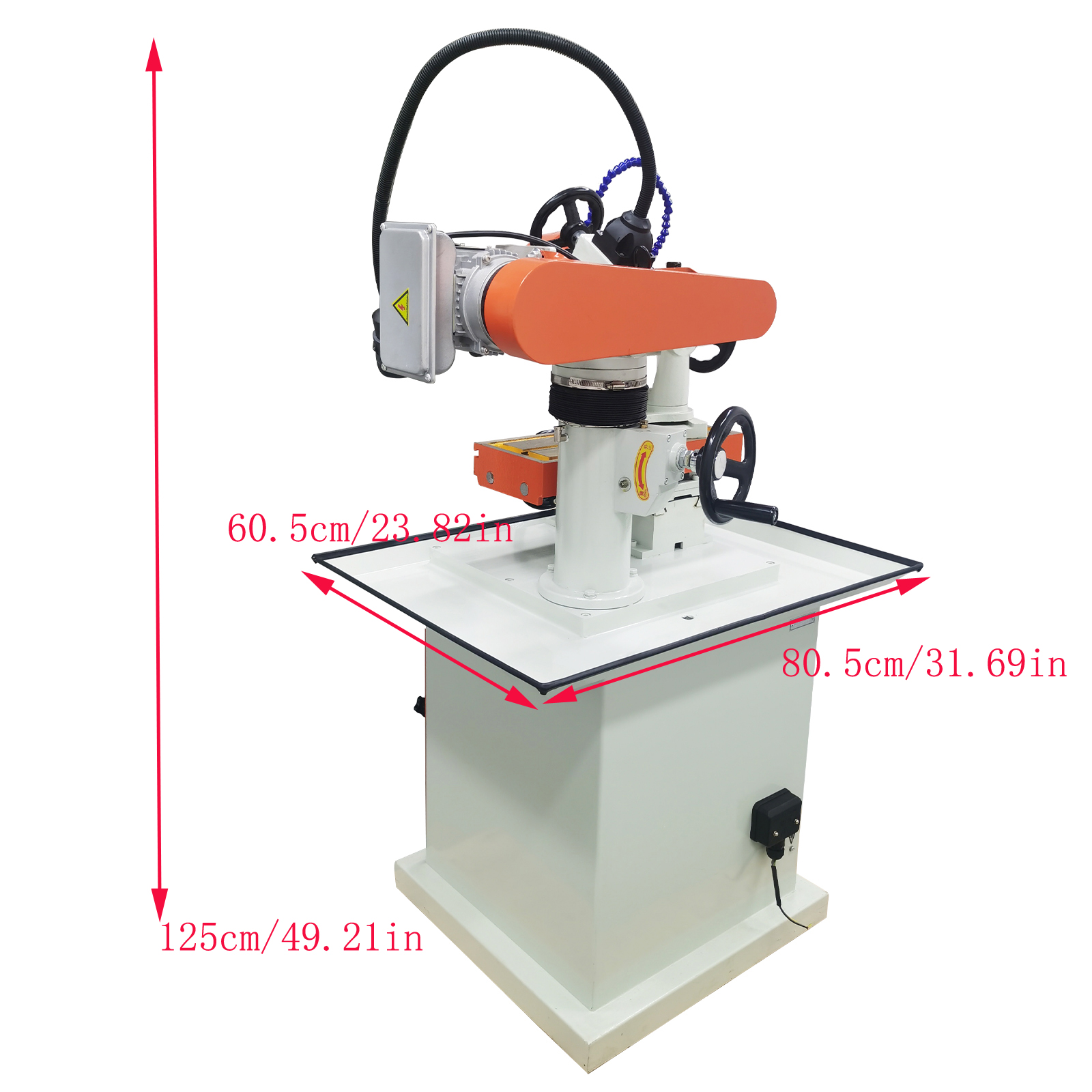

2.Oil should be added to the track every shift, as a knife grinder is a relatively precise blade grinding machine. Therefore, it is necessary to maintain the cleanliness of the track and knife holder shaft when using it.

3.When lifting and lowering the spindle, please pay attention to releasing the locking handle, and each adjustment part should be filled with lubricating oil every shift. The lifting column should not stay in a certainplace for a long time, and should be lifted and lowered several times frequently.

4.After each use, make sure to place the workbench in the middle and do not push the workbench too hard to avoid deformation of the track due tolarge impact forces.

5.The equipped protective cover must be used to ensure the safety of the machine tool and the operator.

6.Individuals who are not familiar with the structure and performance of this machine tool are not allowed to operate to avoid accidental damage to the machine too.

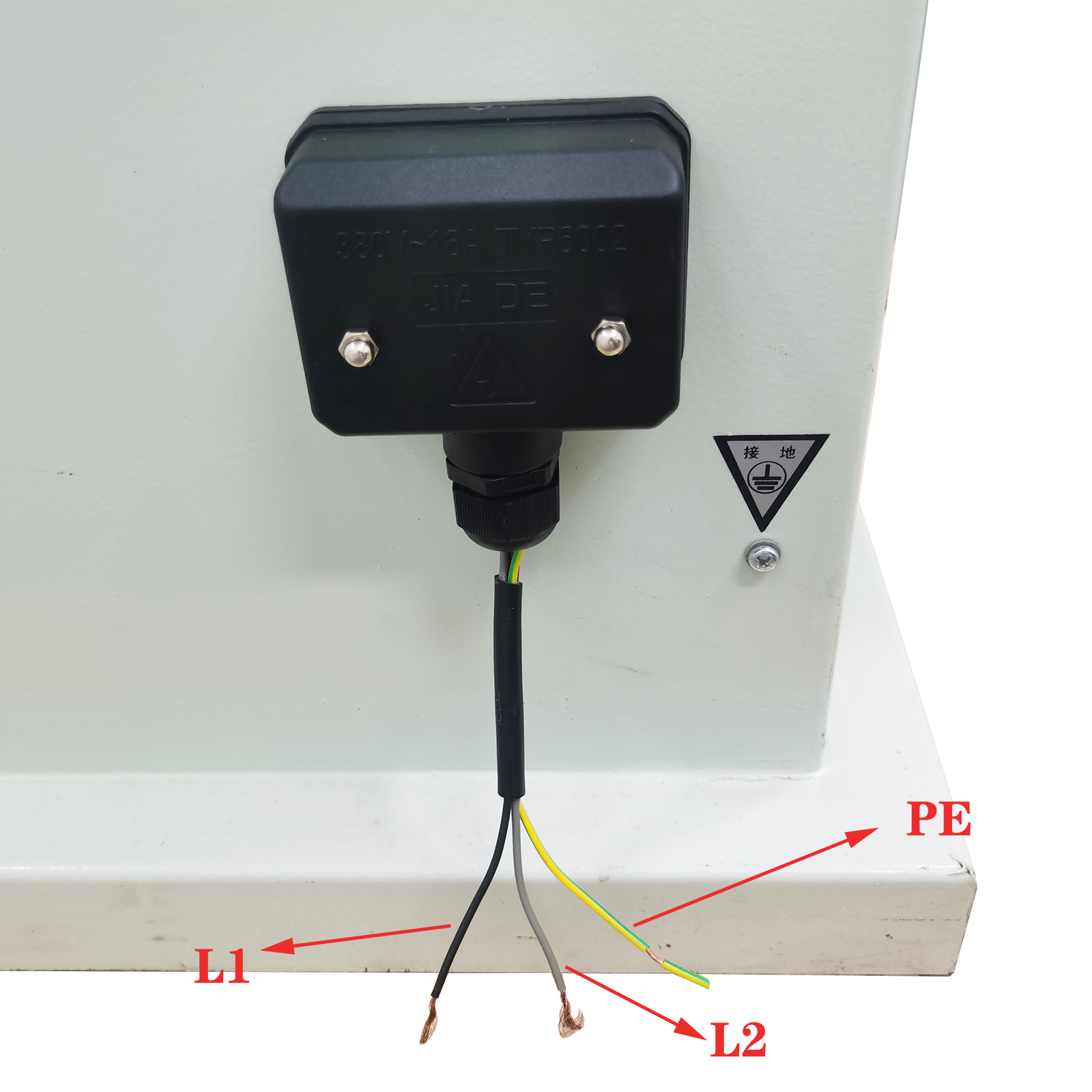

The power cord needs to be provided by the customer, and the machine is only a test line. The wiring method is as follows.

You can make

order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.