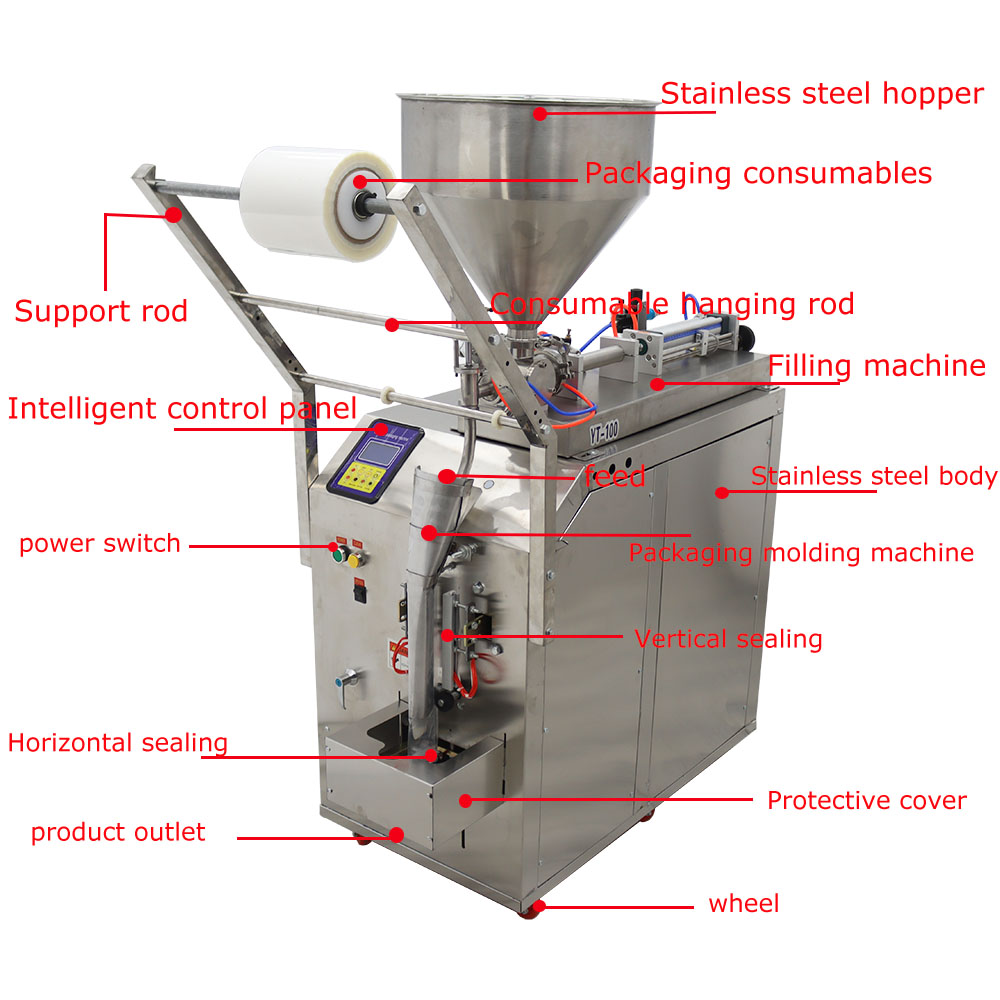

110V 10-100ml Automatic Quantitative

Paste Liquid Filling Machine

The paste liquid filling machine adopts microcomputer control, set by an induction signal processed by a microcomputer, and, simultaneously.the cursor positioning, automatic detection and automatic fault diagnosis and display on the screen.

2.The filling volume range is between 10ml - 100ml. And the machine should connect air compressor for working. First time when you use the machine , you should weigh the weight of output by adjusting and make sure the volume you want.

3.This series of models need to be equipped with external air compressor, air compressor exhaust should not be less than 0.1m3/min, equipped with pressure should be able to adjust to 0.4-0.9Mpa range.

(Note1:We only sell

machines, do not match air compressors, customers need to buy their

own.)

(Note2: If you are not sure whether the material can be filled with this

machine, please consult before placing an order)

Voltage: 110V

Power: 0.5KW

Size: 87*50*141CM(34.25”*19.68”*55.5”)

Filling and packaging speed: 20-30 bags per minute

Material: stainless steel

Packaging: export wooden box

Applicable packaging consumables film width: 6.3in (16CM)

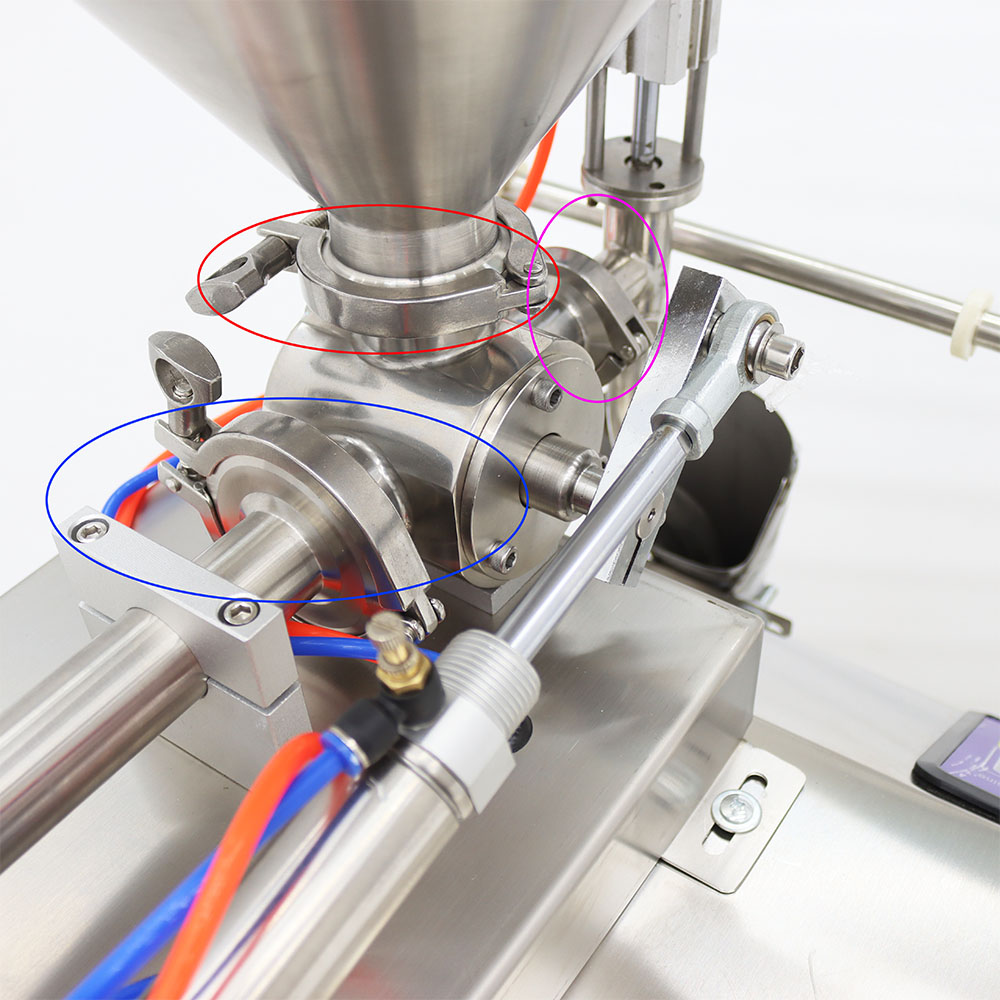

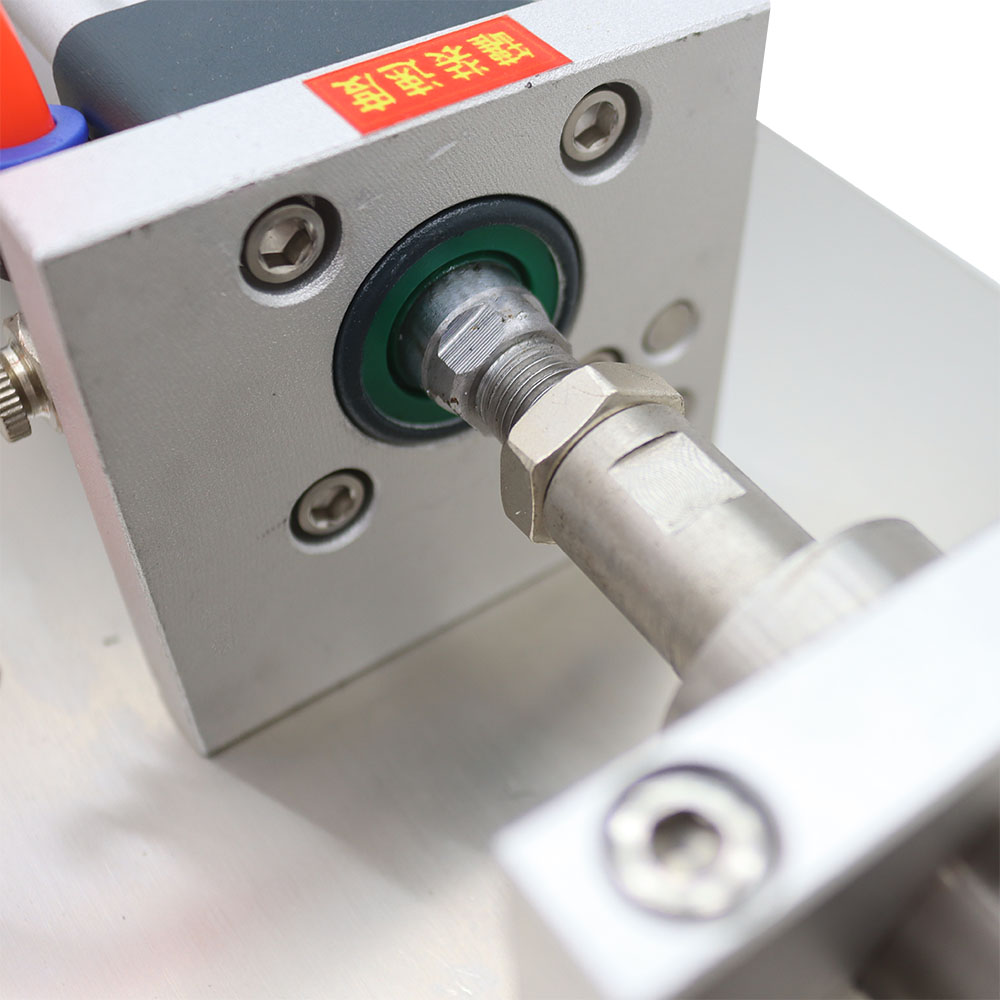

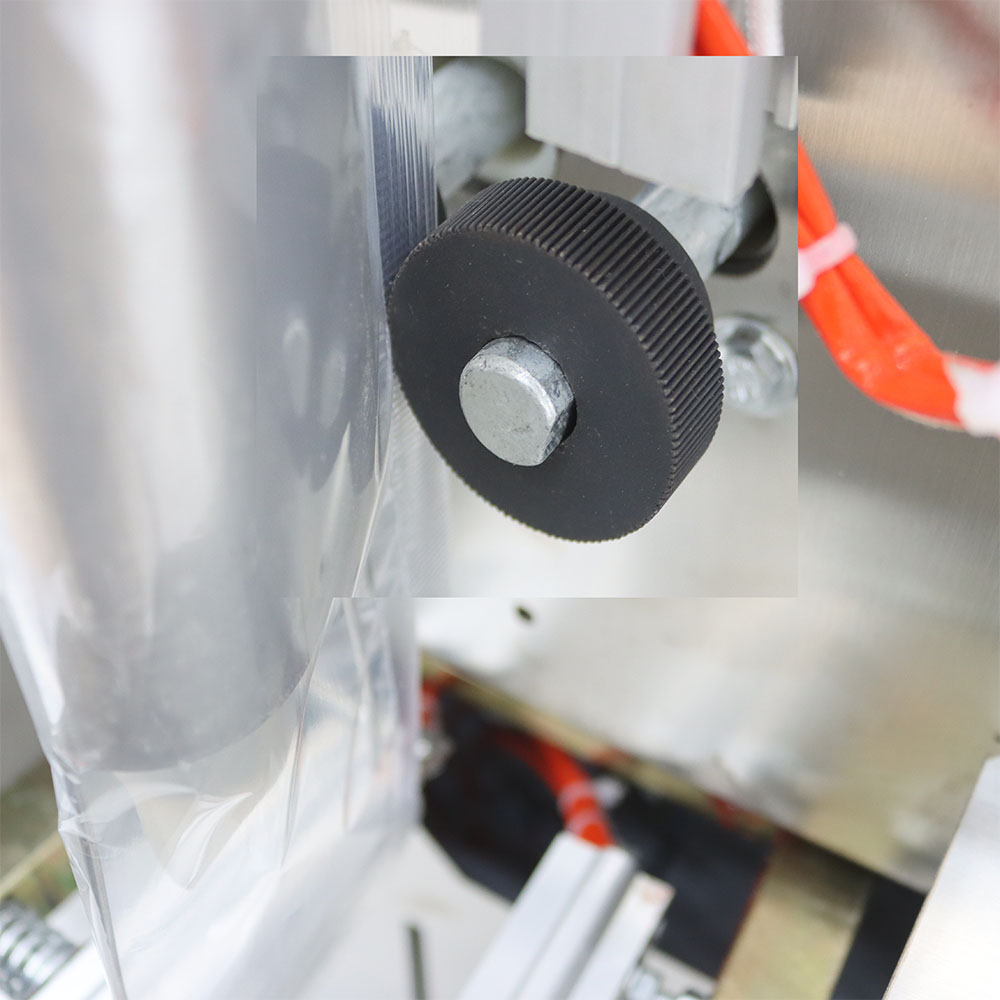

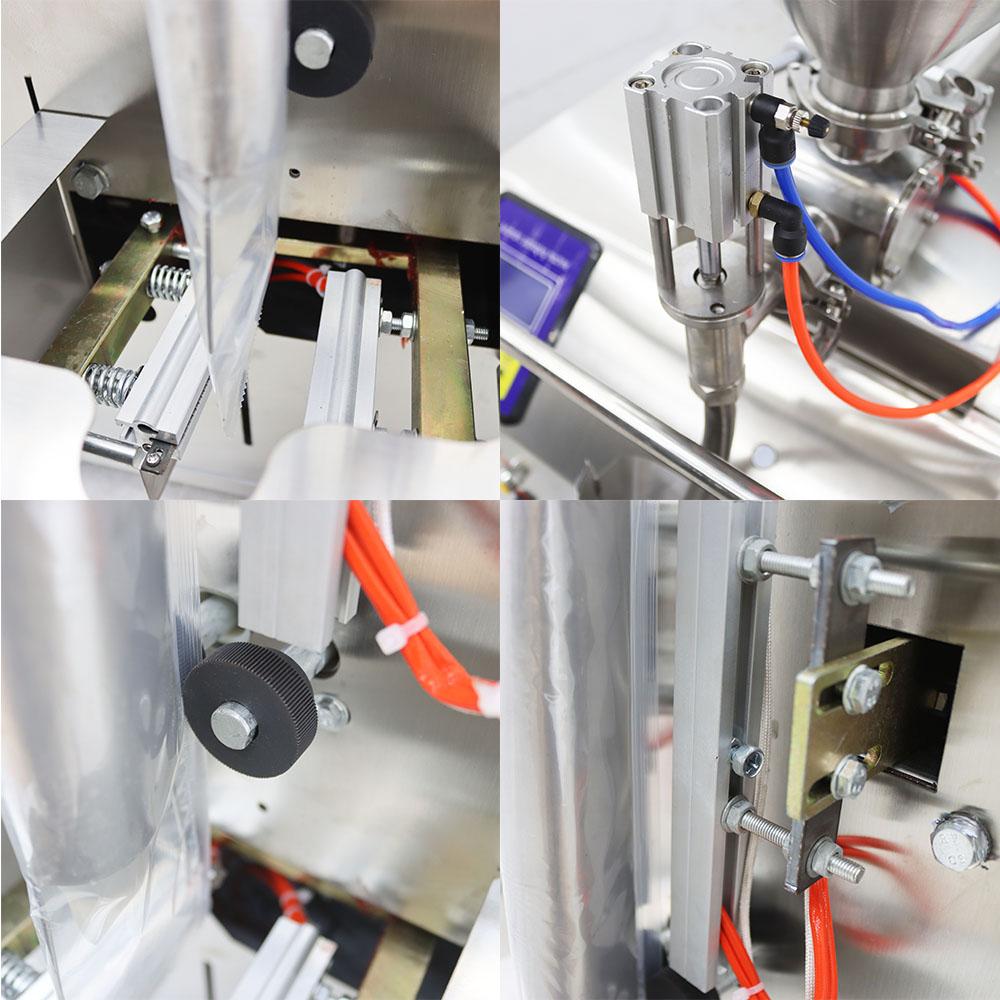

Adjust the rocker

filling precision

Hand handle, you can adjust the amount of filling, easy to operate.

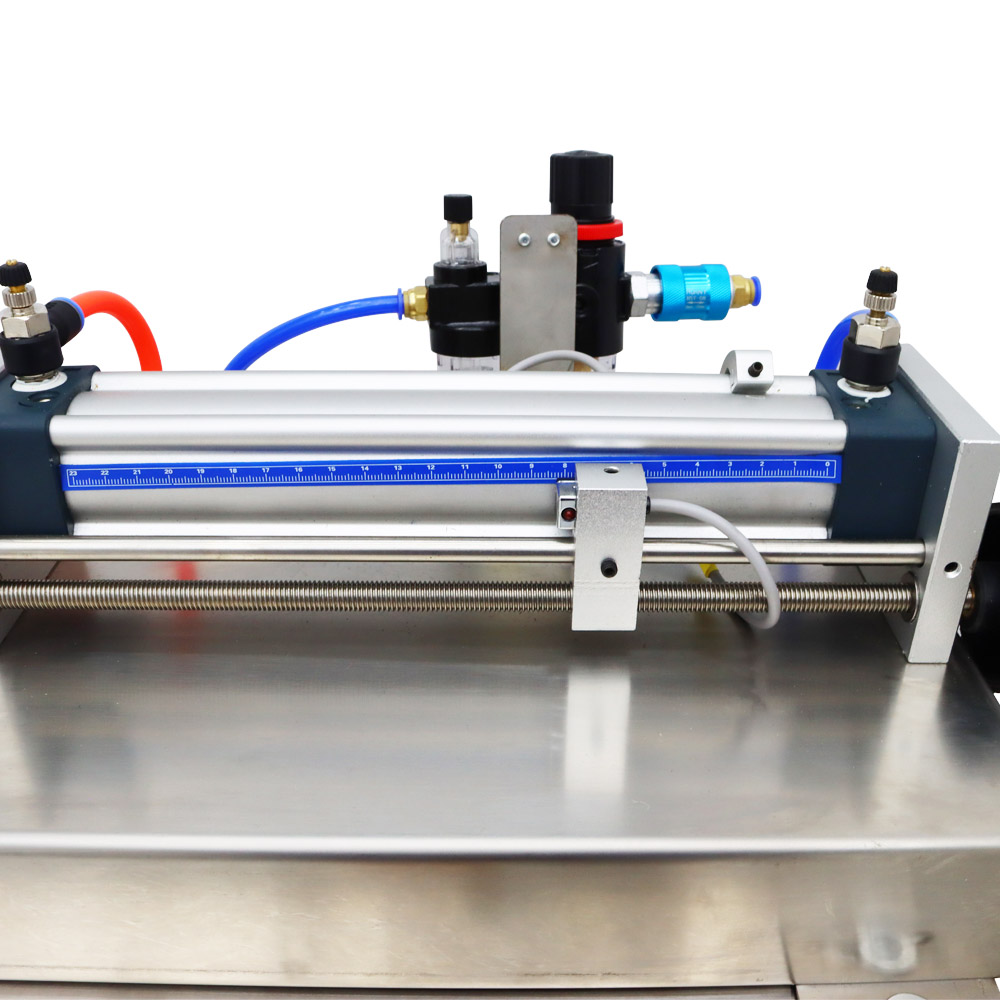

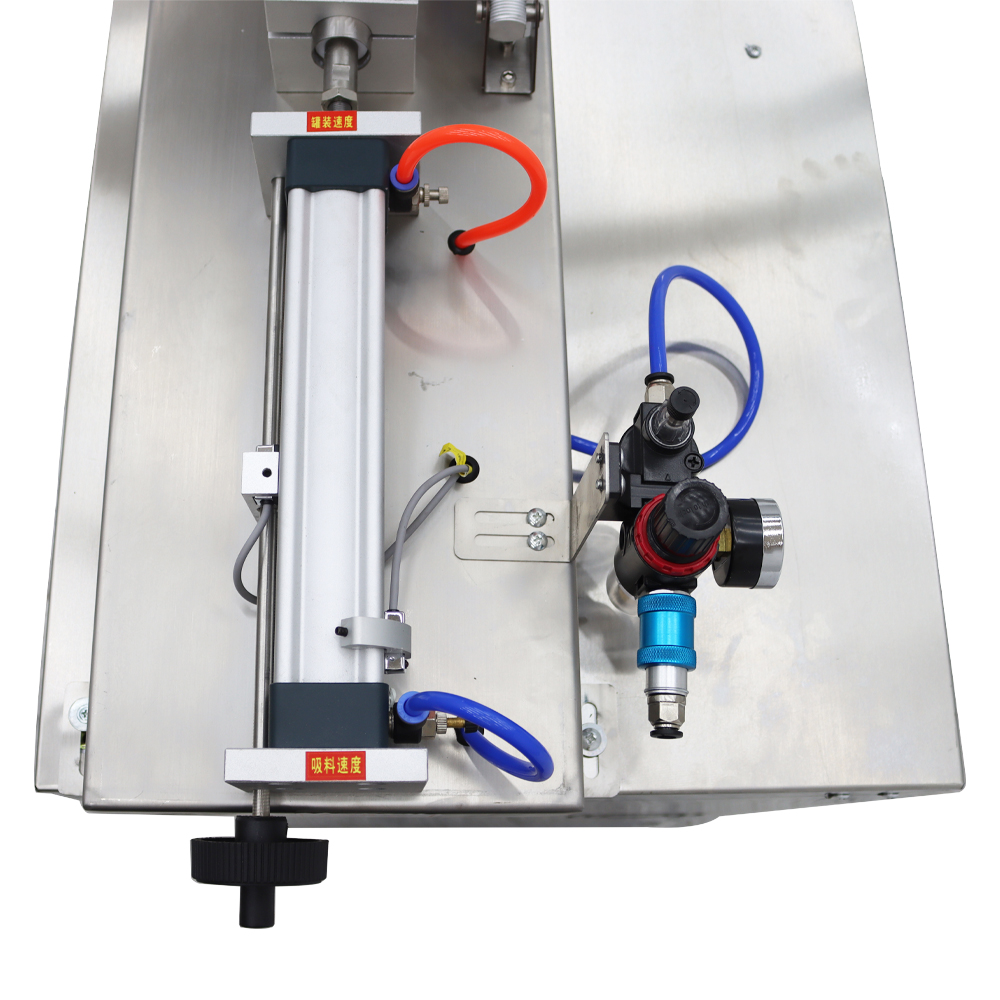

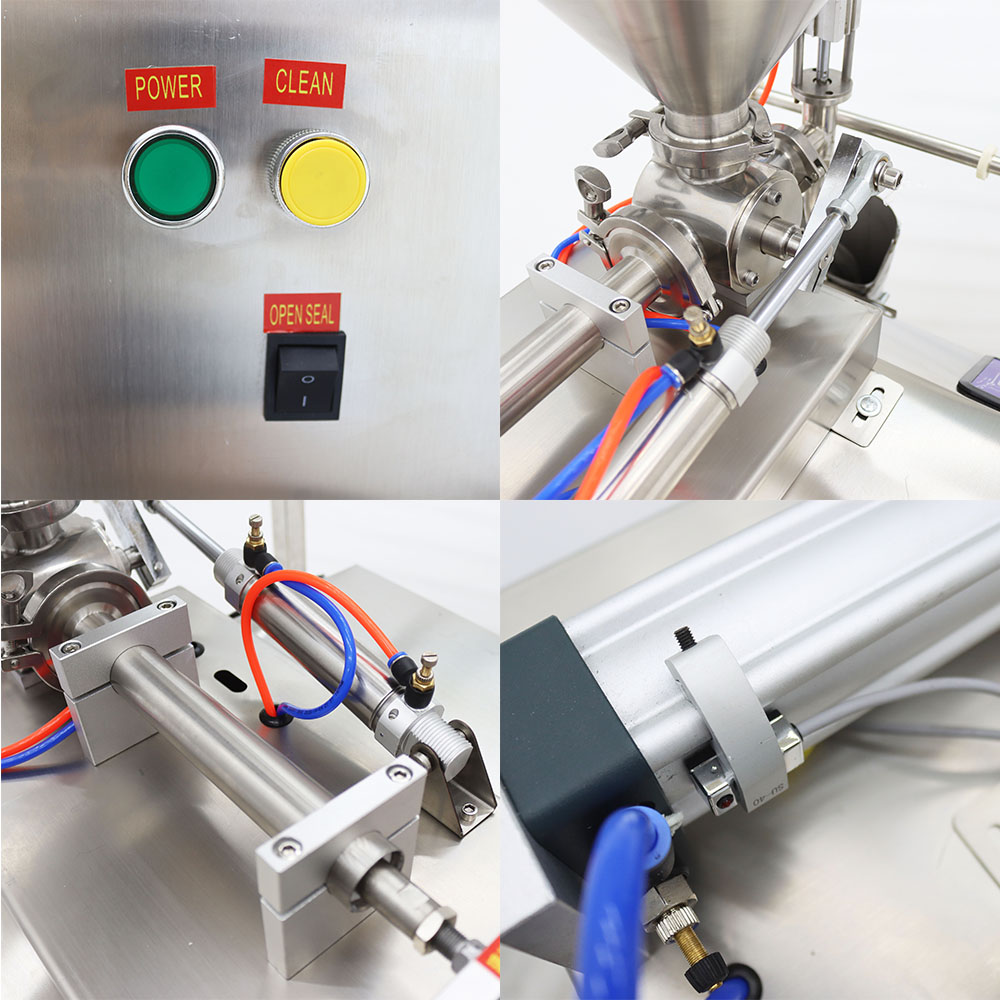

High quality cylinder

This machine is equipped with high-quality air cylinder, which can change the filling speed by adjusting the inlet and outlet flow through the regulating valve.

The operation is simpler, the measurement is more accurate, and the upgrade and maintenance are more convenient. Equipped with counting function, convenient for work counting.

The machine is equipped with a one click cleaning function to automatically clean the internal channels, making it suitable for switching between multiple material packaging in one machine.

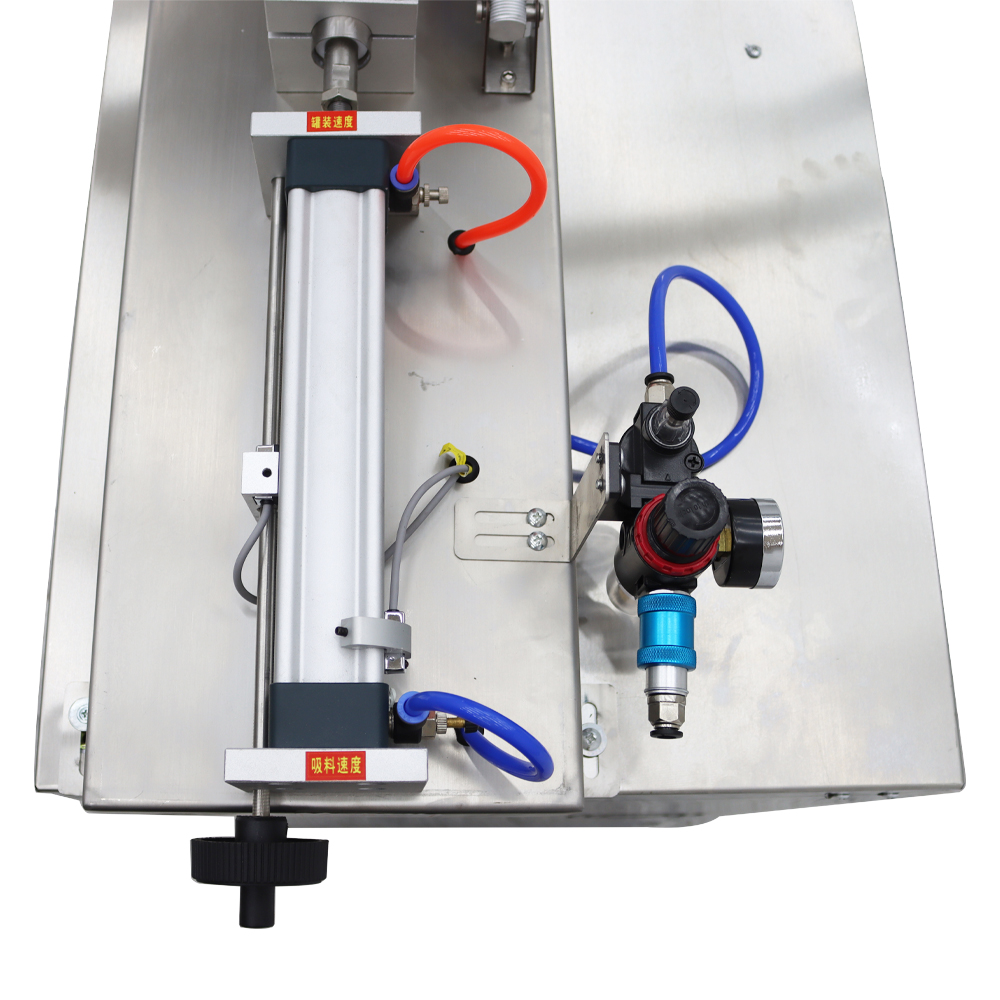

Adjust the speed of

the cylinder moving piston rod:

The end near the moving rod (away from the handwheel) is the outlet

control valve (Adjust the speed of the cylinder moving rod to push out

the material);

The end away from the moving rod (near the handwheel) is the intake

control valve (Adjust the speed of cylinder moving rod recovery).

Clockwise downward, the discharge speed becomes slower;

Counterclockwise upward, the discharge speed becomes faster.

To ensure safe

production, please read the following precautions carefully:

1. Use a power supply and air source that conforms to the requirements

of this machine . The stability of the air source must be maintained

under continuous working conditions.

2. Before disassembling, washing or repairing this machine, please be

sure to turn off the air source and power supply first.

3. Under no circumstances should the entire machine be directly washed

with water, as there is a risk of electric shock and damage to

electrical control components.

4. After the power switch is turned off, there is still voltage in some

circuits in the electrical control of this machine. When repairing the

control circuit, please be sure to unplug the power cord.

5. Do not approach the vertical and horizontal seals when the machine is

working to prevent burns.

6. Do not put your hand on the central axis of the cylinder during the

work process, pay attention to pinching your hands.

7. Before using materials for filling, it is best to clean the machine

with detergent first, and then clean it with clean water, so as to avoid

oil stains or foreign materials and materials mixing, which will lead to

waste of materials and damage to the machine.

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.