|

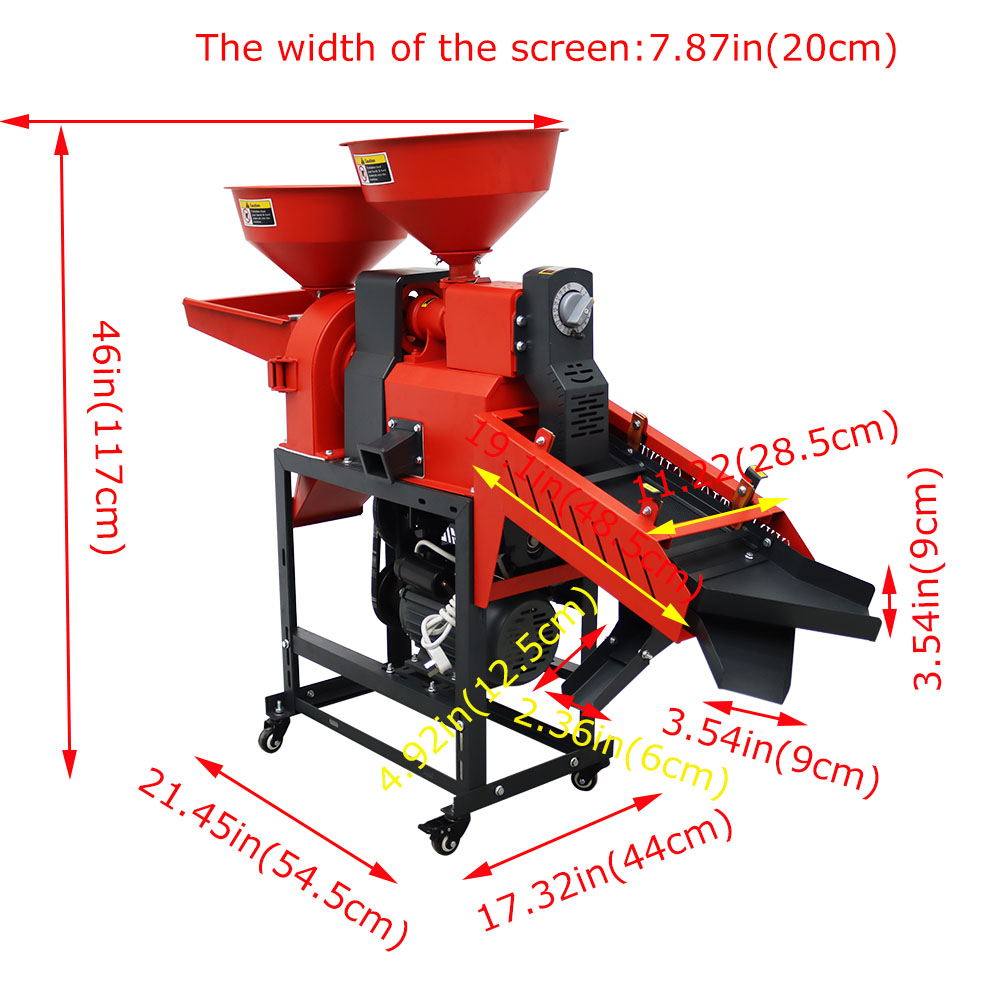

Rice mill and crushing machine with vibrating screen |

|||||||||||||||||

|

This machine can achieve the peeling function of rice and millet, as well as the crushing function of rice, millet, and corn. It is suitable for households, livestock farms, traditional Chinese medicine stores, farms, pastures, pet farms, fish farms, feed factories, and so on. The rice and millet enter the rice milling chamber through the feeder, and then the rice is squeezed by the bearings and rice blades. In this step, the rice will be hulled and discharged to the discharge port, with a unique discharge port design separating the whole rice from the broken rice. The broken rice bran will enter the bran bag through a sieve, and users can use bran powder as feed. Rice and millet enter the crushing chamber through a feeder. In this step, the material will be crushed and discharged to the discharge port. The crushed rice bran will enter the rice bran bag through a sieve, and users can use rice bran powder as feed. |

|||||||||||||||||

|

|

|||||||||||||||||

|

Note:

1.The machine should be

placed in a dry, bright and ventilated environment; |

|||||||||||||||||

| Product parameter: | |||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

| Product analysis: | |||||||||||||||||

|

|||||||||||||||||

|

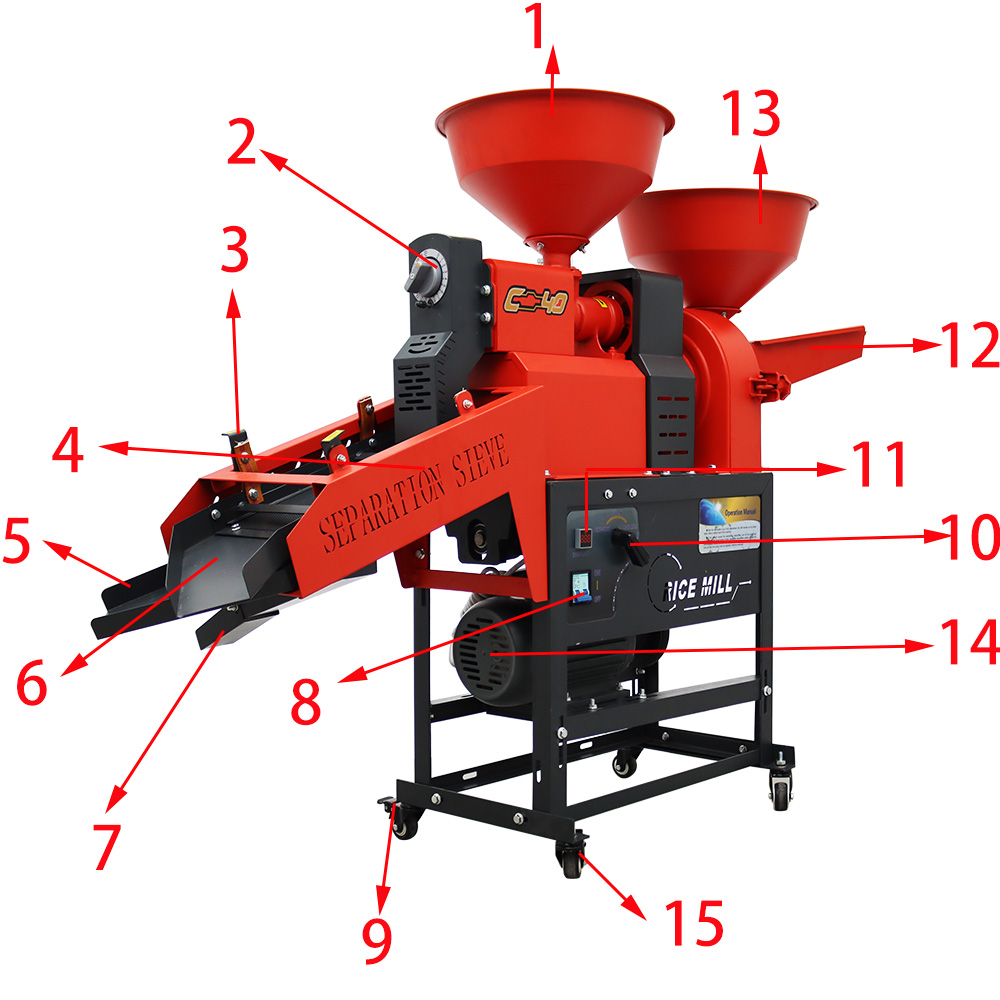

1.Feed hopper 2.Flow meter flow regulator 3.Speed adjustment of vibration screen amplitude 4.Vibrating screen 5.Medium meter discharge port 6.Whole meter discharge port 7.Broken rice discharge port 8.Air Switch 9.Mobile wheel with foot brake 10.Switching switch between rice milling machine and pulverizer 11.Voltage display screen 12.Feeding inclined hopper 13.Feed hopper 14.High quality motor 15.Castor without foot brake

|

|||||||||||||||||

| Feature: | |||||||||||||||||

|

Meter flow regulator Adjust this to adjust the flow rate of rice, which is the quality of rice. If the rice is milled too fast, it will not be as clean and the quality will be lower. Conversely, if the rice is milled slower, the quality will be cleaner. |

||||||||||||||||

|

Increase the feeding

port |

|

||||||||||||||||

|

This machine is equipped with a multi-layer vibrating screen, with the top layer producing complete rice, the second layer producing medium rice, and the smallest opening on the side producing crushed rice. This can help customers better achieve the separation of rice quality, making it more practical and convenient. | ||||||||||||||||

|

This machine is

equipped with air switch, which is safer and more secure. This machine is equipped with a voltage display screen for a more intuitive reference to whether the voltage is stable. This machine is equipped with a switch between a rice milling machine and a pulverizer, which can achieve one key switching and dual use of one machine. |

|

||||||||||||||||

|

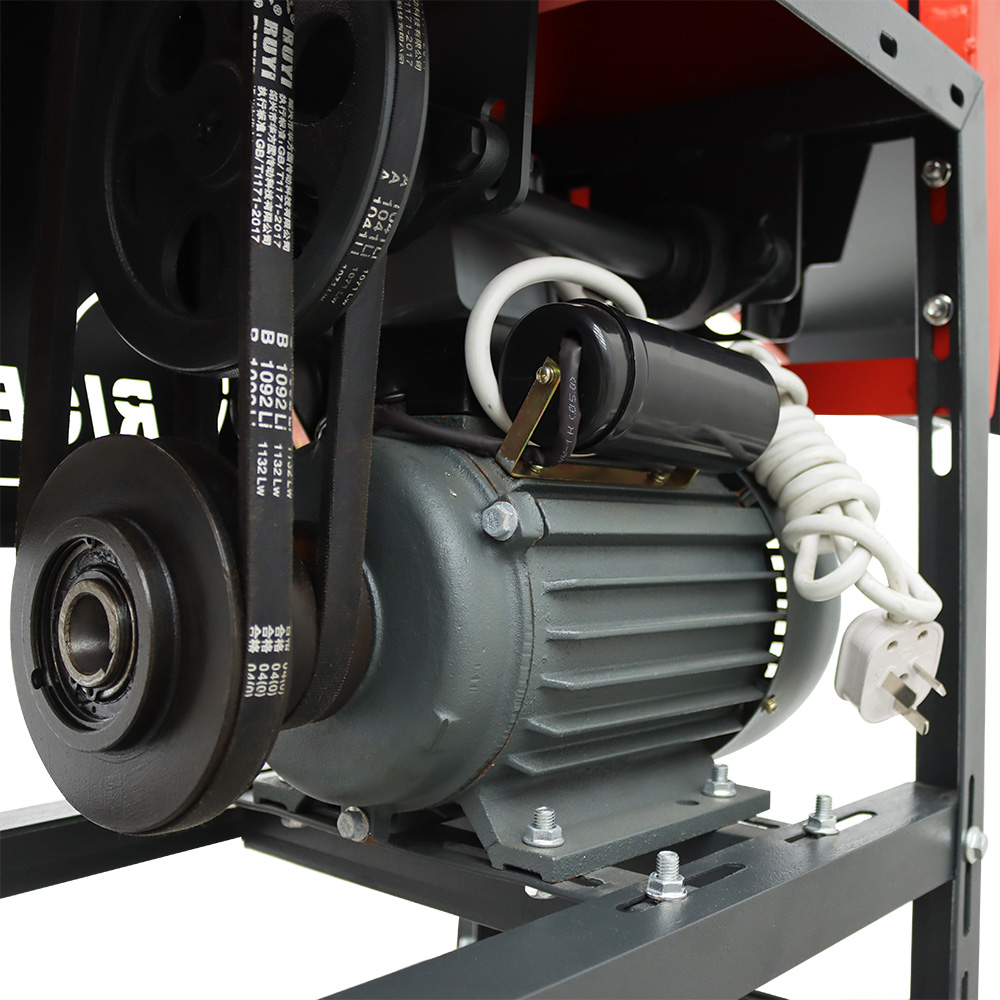

This machine is equipped with high-quality high-power motor. | ||||||||||||||||

| The whole machine adopts a thickened bracket, which is sturdy and durable, not easily deformed, more durable, and has a longer service life. |

|

||||||||||||||||

|

The adjustment plate for the opening size of the feeding hopper allows you to choose the diameter size of the material to be placed, making it more convenient and practical, with diverse choices. | ||||||||||||||||

| The bran outlet allows for the bag to be placed and fixed here to collect bran for use in making feed. |

|

||||||||||||||||

|

This is the adjustable vibration screen amplitude, which customers can adjust according to their needs. | ||||||||||||||||

| This machine is equipped with two casters with foot brakes for easy movement. |

|

||||||||||||||||

|

This machine is equipped with two casters without foot brakes for easy movement. | ||||||||||||||||

| Precautions for operation: | |||||||||||||||||

|

In order to ensure the safety and normal operation of the person and the machine, a special person shall be assigned to be responsible for the storage and use of the machine. The machine shall not be operated without learning this procedure and operation technology and reading the familiar instructions. Please check the machine before the first use. 1.Whether the triangle belt is too loose or too tight; the triangle belt should be kept parallel and perpendicular; 2.Whether each assembly bolts are fastened; 3.Whether the motor is installed in parallel; 4.Whether the rotation direction of the motor and machine is correct; 5.The power cord shall not be damaged; 6.The protective cover shall be well assembled; 7.After checked the completion of 1-6 precautions, turn the power supply on to make the machine running idly for 1-2 minutes. 8.Prohibit the minors and the elderly from operating the machine; 9.Prohibit the handicapped from operating the machine; 10.Do NOT operate the machine after drinking; 11.Make the machine running idly for inspection before each use; 12.Do NOT feed agricultural materials before starting the machine; 13.Do NOT remove the protective cover when operating the machine; 14.If abnormal noise is detected, turn off the power immediately, pull out the plug and then inspect the machine; 15.No metal or the hard stuff can be mixed in the agricultural materials (if metal or the hard stuff entered the machine, turn off the power in time for cleaning); 16.If the machine breaks down, metal or the hard stuff enters the machine, stop the machine and clear fault. Rotate the machine by hand to check whether the machine is normal and whether each component is damaged. The test of running machine idly must be implemented to ensure that no damage to each component and the machine is intact before starting the power supply and pouring in the agricultural materials. (The operator is not allowed too near the machine when starting the power. The machine can continue to operate after normal running idly);

|

|||||||||||||||||

| Details: | |||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

Different places have different Receptacles. Please note this plug and consult your electrician before purchase. We suggest that high-power machines should be directly connected to the main power supply, as the voltage reaching the machine is stable. If the voltage is unstable and the current exceeds the rated current of the motor, it is easy to burn out the starting capacitor.

|

|||||||||||||||||

|

Step 1 Loosen the three screws at the hopper opening, place the hopper in place and secure it with screws. |

|

||||||||||||||||

|

Step 2 Loosen four screws, remove the spacer, install the inclined inlet hopper, and then install the spacer.

|

|

||||||||||||||||

|

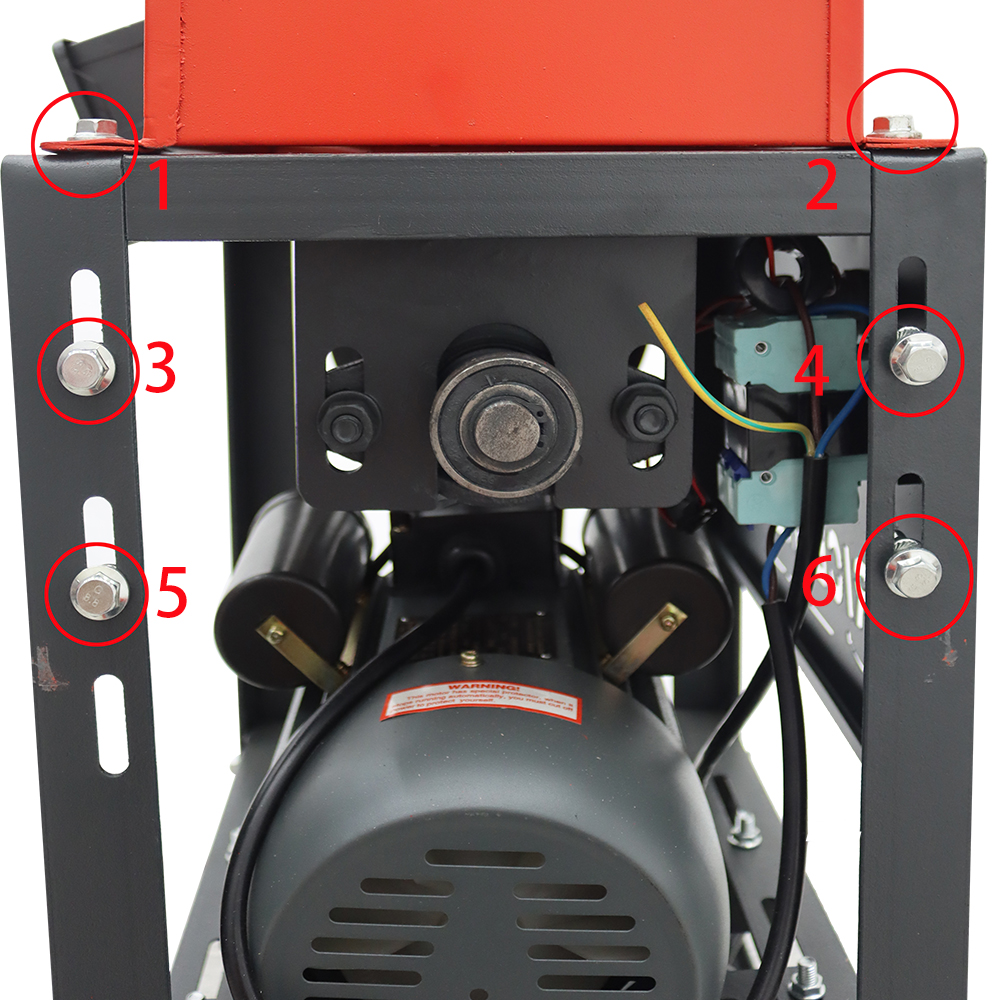

Step 3 Loosen the 6 screws on the body and secure the discharge screen.

|

|

||||||||||||||||

|

Step 4 Loosen the 4 screws on the machine and fix the installation of the flow meter flow regulator;

|

|

||||||||||||||||

|

Step 5 Install three layers of rice outlet(it is recommended to install the lower layer first for convenience)

|

|

||||||||||||||||

|

Product display: |

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

|

|||||||||||||||||

|

|||||||||||||||||

| Item Number: 1*Rice milling and crushing machine with vibrating screen (239791) | |||||||||||||||||

|

You can make order

with no worry. |

|||||||||||||||||