Instructions for using the mud machine

The mud machine is mainly used to

evenly mix clay and other raw materials to make mud suitable for the

production of pottery products

The use of clay drilling machine not only improves the efficiency of

pottery, ensures the quality of pottery, but also reduces manual labor,

for pottery enthusiasts, the operation of clay drilling machine is

simple, and it can easily produce a variety of shapes of pottery.

In addition, the mud machine is also suitable for other fields, such as

the production of standardized concrete to ensure the quality and

strength of concrete.

| Voltage: | 220V |

|

Power: |

1.5KW |

|

mud production: |

150 kilos an hour |

|

mud outlet diameter : |

60mm |

|

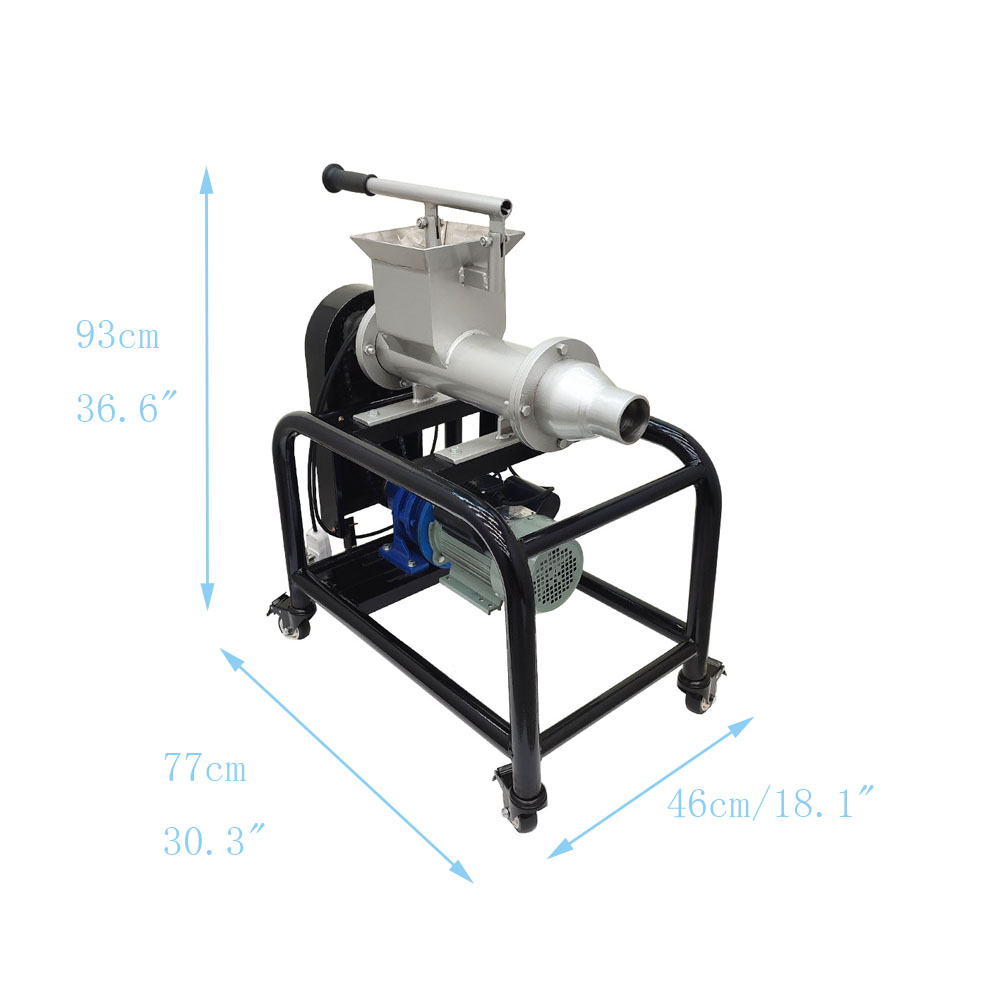

Main dimensions weight: |

30.3*18.1*36.6 83KG |

Function introduction:

1, safe, light weight, greatly reducing the noise of the machine

2, the use of inverter drive motor, high efficiency and low energy consumption, is conducive to reducing production costs

3, the mud cylinder can be detachable structure, easy to clean up the mud in the mud cylinder

Installation environment requirements:

1. The equipment should be placed on a cool, ventilated, dry, dustproof and good level ground;

2. The user must install the wiring according to the safety standard of electricity consumption. Single-phase and three-phase power must be supplied by a power grid with ground wires. The device can be put into operation only when there is a grounding cable. Do not run the device without a grounding cable. Single-phase AC220V±10%;

3. Ambient temperature 0 ~ 50 degrees Celsius, no corrosive and no strong electromagnetic field radiation occasions;

4. The working area of the equipment should maintain air circulation to avoid overheating and burning the motor.

5. Arrange power cables and sockets correctly;

6. Do not place any items on the machine itself;

Operation procedure:

Operation process: installation check (accessories check, power-on test machine check) → Power on → switch on the mud mill → mud input → initial training → refining extrusion → Get dense plastic mud from the discharge port → Stop feeding → Turn off the mud mill switch → Turn off the power → Clean the equipment

Operation instructions and precautions:

Power on

First open the mud machine and then evenly put the mud into the bucket,

and pump the mud together to pump out the bubbles in the mud.

Shut down

The shutdown steps are as follows:

1, there is no mud inside the mud machine bucket and the mud mouth does not produce mud

2. Open the air valve to exhaust

3. Stop the mud machine

4. Take a wet cloth and put it in the bucket to keep the moisture in the mud

5. Use plastic bags to seal the bucket and mud nozzle.

Note:

1, dry mud can not be put into the bucket, recycling mud can not have garbage and debris.

2, the mud is not used for a long time, it should be started every half a month.

3, do not put debris, or hand into the mud mouth, to avoid accidents!

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.